BLDC Motor: Comprehensive Guide to Brushless Motors

Published by Alok Jain on 24th Nov 2024

In the world of modern engineering, BLDC motors have made a big splash. These brushless DC motors are changing the game in various fields, from drones and electric vehicles to industrial machinery. You'll find them powering everything from tiny gadgets to large-scale equipment, thanks to their impressive torque and efficiency. As technology keeps moving forward, BLDC motors are becoming more and more important in shaping the future of electric power systems.

This guide will give you the lowdown on BLDC motor technology and why it's such a big deal. We'll explore the perks of using these motors and help you figure out how to pick the right one for your needs. You'll also get a peek at some real-world applications, showing how these motors are making waves in different industries. By the end, you'll have a solid grasp of BLDC motors and their role in today's tech landscape.

Table of Contents:

- Understanding BLDC Motor Technology

- Advantages of BLDC Motors

- Selecting the Right BLDC Motor

- Applications of BLDC Motors

- Conclusion

- FAQs

Understanding BLDC Motor Technology

Explore BLDC Motor Technology essentials—learn how brushless motors deliver efficient, high-performance power for diverse applications, enhancing longevity and reducing maintenance. Dive into the principles, benefits, and uses of these versatile motors in modern systems.

Definition and Basic Principles

Brushless DC motors (BLDC) are a type of electric motor that has made a big splash in various fields, including drones and electric vehicles. Unlike traditional DC motors, BLDCs don't use brushes for commutation. Instead, they rely on an electronic controller to switch the current in the motor windings. This setup allows for better efficiency and longer life.

The basic principle behind BLDC motors is similar to other electric motors. It's all about the interaction between magnetic fields. In a BLDC motor, you've got a rotor with permanent magnets and a stator with windings. When you power up these windings in the right sequence, it creates a rotating magnetic field. This field interacts with the permanent magnets on the rotor, causing it to spin.

Components of a BLDC Motor

A BLDC motor has three main parts:

- Stator: The stator is the stationary part of the motor. It's made up of steel laminations with slots cut along the inner surface. These slots hold the windings, which are typically arranged in a three-phase star configuration.

- Rotor: The rotor is the part that spins. It contains permanent magnets, usually made from materials like neodymium or samarium cobalt. These magnets can be arranged in different ways, depending on the motor's design and intended use.

- Electronic Controller: The electronic controller is the brains of the operation. It uses sensors to figure out where the rotor is and then energizes the right stator windings at the right time. This is what replaces the mechanical commutation you'd find in a brushed DC motor.

How BLDC Motors Work

The working principle of BLDC motors is pretty neat. When you apply power, the controller energizes two of the three stator windings. This creates a magnetic field that interacts with the permanent magnets on the rotor. The rotor then aligns itself with this field, causing it to rotate.

As the rotor spins, the controller keeps switching which windings are energized. This keeps the magnetic field rotating, and the rotor follows along. The controller uses feedback from sensors (often Hall effect sensors) to know when to switch the windings.

This electronic commutation is what gives BLDC motors their edge. It allows for precise control over speed and torque, making them ideal for applications that need both power and accuracy.

Advantages of BLDC Motors

BLDC motors offer significant advantages: higher efficiency, reduced noise, and longer lifespan due to their brushless design. Ideal for precision applications, they provide smooth operation, lower maintenance, and greater speed control, making them a preferred choice across industries from automotive to consumer electronics and robotics.

High Efficiency and Performance

BLDC motors have made a big splash in the world of electric power systems, and for good reason. These motors are super efficient, converting up to 90% of electrical energy into mechanical power. This means they waste less energy as heat, making them a top choice for applications where energy savings matter. In electric vehicles and drones, this high efficiency translates to longer battery life and improved performance. Industrial machinery also benefits from BLDC motors, as they can run continuously with lower operating costs.

Longevity and Low Maintenance

One of the coolest things about BLDC motors is how long they last. Without brushes rubbing against a commutator, there's way less wear and tear. This means these motors can keep running for a whopping 20,000 hours or more! That's over two years of non-stop operation. This extended lifespan is a game-changer for industries that need reliable, long-lasting equipment. It cuts down on maintenance time and costs, which is great news for businesses looking to maximize uptime and productivity.

Precise Speed Control

When it comes to controlling speed, BLDC motors really shine. Thanks to their electronic commutation system, you can adjust and control the motor's speed with incredible precision. This makes them perfect for applications that need spot-on accuracy, like robotics or medical devices. The motor can maintain a constant speed even when the load changes, which is super helpful in many industrial settings. Plus, BLDC motors can start, stop, and reverse direction quickly, giving you more control over your equipment's movement.

Selecting the Right BLDC Motor

Choosing the right BLDC motor involves considering factors like torque, speed, efficiency, and control requirements. By aligning motor specifications with application needs—whether in robotics, automation, or vehicles—you can ensure optimal performance, energy savings, and reliability. Get insights on finding the perfect fit for your project’s unique demands.

Motor Specifications to Consider

When choosing a BLDC motor, you need to look at several key specs. First up, check out the voltage and current ratings. These should match your power supply and the demands of your application. Next, consider the motor's power rating, which tells you how much oomph it can deliver. Don't forget about the speed range either – make sure it fits what you need.

Another crucial factor is the torque rating. This tells you how much turning force the motor can produce. For high-power applications (over 70W), you might need to look at gate drivers instead of integrated FET solutions.

Matching Motors to Application Requirements

To pick the right BLDC motor, you've got to know what your application needs. Are you looking for high speed or high torque? Maybe you need both? For example, if you're working on drones, you'll want a motor that can handle speeds between 9,000 to 15,000 RPM. But for electric boats, you might need something that can hit 20,000 to 35,000 RPM.

Don't forget about the environment your motor will be working in. Some BLDC motors can handle tough conditions better than others. If you're dealing with high temps or need to sterilize your equipment, that'll narrow down your options.

Common Pitfalls to Avoid

One big mistake people often make is choosing a motor based solely on its kV value. While this can be important, it's not the whole story. You need to consider how the kV value works with your battery pack to give you the right RPM for your application.

Another common error is not thinking about heat dissipation. If your motor can't get rid of heat fast enough, it'll burn out. To avoid this, make sure you pick a motor with the right can size for the amount of power you plan to draw.

Lastly, don't forget about inertia matching, especially if you're using closed-loop speed control. If the load inertia is too high compared to the motor inertia, you could end up with an unstable system.

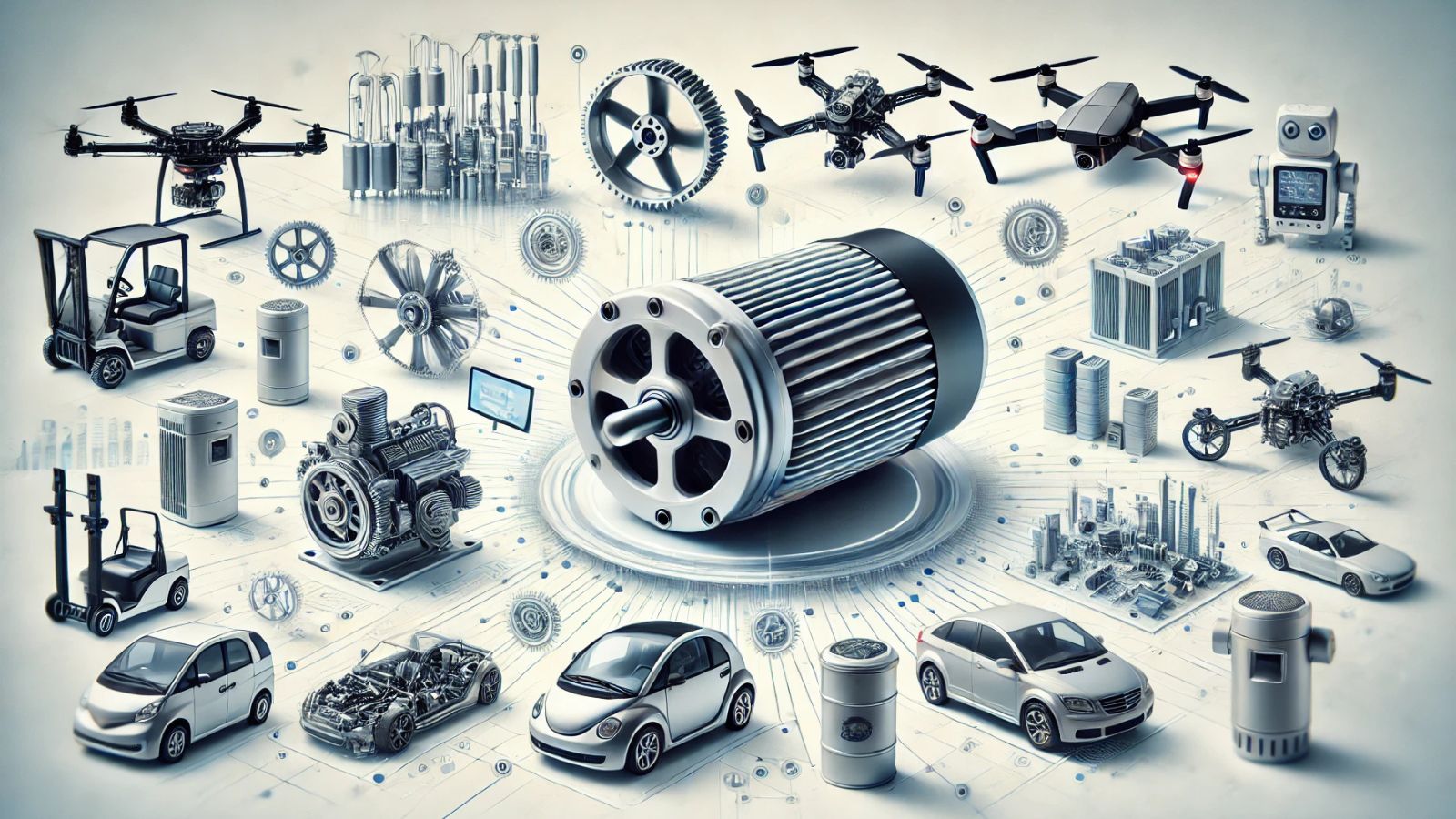

Applications of BLDC Motors

BLDC motors power a variety of applications—from electric vehicles and drones to HVAC systems and home appliances. Their efficiency, durability, and precision make them ideal for industries requiring reliable, high-performance motors, such as robotics, automotive, and consumer electronics.

Consumer Electronics

BLDC motors have made a big splash in consumer electronics, reshaping how we use technology every day. These motors are super efficient, converting up to 85% of electrical energy into mechanical power. This is a game-changer for battery-powered gadgets like smartphones and laptops, where longer battery life is key. In smart home appliances, like robotic vacuum cleaners, BLDC motors pack a punch in a compact design. They're also great for audio equipment, running cooling fans with minimal noise to keep your tunes crystal clear.

Automotive Industry

The automotive world is embracing BLDC motors in a big way. You'll find them in electric vehicles, providing smooth acceleration and helping to extend driving ranges. They're also used in power steering systems, making your drive more responsive. BLDC motors are perfect for air conditioning compressors and fans too, keeping you cool without draining your battery. Even in traditional cars, these motors are popping up in everything from window controls to adjustable seats, making your ride more comfortable and efficient.

Industrial Automation

BLDC motors are changing the game in industrial automation. They're ideal for robotics, CNC machines, and conveyor systems, offering precise control and high reliability. These motors can handle tough conditions and keep running for long periods without overheating. This makes them perfect for continuous manufacturing operations where downtime isn't an option. Their compact size and high power density also mean they can pack a lot of punch in a small package, which is great for space-saving designs in factories.

Aerospace and Drones

In the aerospace industry, BLDC motors are soaring high. NASA has been using them for over 50 years, from powering rovers to running life support systems in spacecraft. These motors can handle the extreme conditions of space, making them crucial for long-term missions. In the world of drones, BLDC motors are the go-to choice. They provide the perfect balance of power, efficiency, and lightweight design that drones need to fly longer and carry more payload. Whether it's a hobby drone or a commercial UAV for mapping or delivery, BLDC motors are keeping them in the air.

Conclusion

BLDC motors have made a big splash in various industries, revolutionizing the way we approach electric power systems. From consumer electronics to aerospace, these motors offer a perfect blend of efficiency, performance, and longevity. Their ability to provide precise speed control while requiring minimal maintenance has made them a go-to choice for applications ranging from tiny gadgets to large-scale industrial machinery.

As technology continues to evolve, BLDC motors are poised to play an even more crucial role in shaping the future of electric power systems. Their adaptability to different voltage and current ratings, coupled with their high torque capabilities, makes them versatile enough to meet the demands of emerging technologies. Whether it's in the development of more efficient electric vehicles or the advancement of robotic systems, BLDC motors are set to remain at the forefront of innovation, driving progress across multiple sectors.

FAQs

Q. What techniques are used to control a BLDC motor?

A. BLDC motors can be controlled using one of three primary methods: trapezoidal, sinusoidal, and field-oriented control (FOC). Trapezoidal control, which is the simplest, involves energizing each phase of the motor in sequence based on rotational information from sensors or back electromotive force (EMF).

Q. How can the speed of a brushless DC motor be adjusted?

A. The speed of a brushless DC motor can be regulated by altering the input DC voltage or current. Applying higher voltage increases the motor speed. Various control algorithms, such as using a power transistor as a linear voltage regulator, are employed to manage the motor voltage effectively.

Q. What factors limit the speed of a BLDC motor?

A. The speed of a BLDC motor is primarily constrained not by its electronic commutation system, which does not suffer from mechanical wear, but by the rotor assembly and the bearings within the motor.

Q. Do brushless motors offer high-speed performance?

A. Yes, brushless motors are known for their high power-to-weight ratio and can achieve high speeds. They allow nearly instantaneous control of speed and torque, offer high efficiency, and require low maintenance compared to brushed motors.