Resources:

Datasheet

Industrial Grade Desktop Selective Laser Sintering System For Nylon PA12 Functional Part Manufacturing

This industrial desktop SLS 3D printer is designed for producing strong accurate and functional nylon PA12 parts directly in house. It enables manufacturers product designers and R and D teams to move from prototype to end use production without outsourcing delays or tooling costs.

Selective laser sintering technology allows complex geometries internal channels and interlocking assemblies to be printed without support structures. The surrounding powder supports the part during printing which results in high dimensional accuracy isotropic strength and excellent surface quality suitable for real world applications.

Built for small and medium enterprises educational institutes and advanced workshops this system delivers industrial grade output in a compact and energy efficient desktop footprint. It supports scalable production faster iteration cycles and cost control while maintaining consistent print quality.

Key Features

-

High Speed Fiber Laser System

Thirty watt fiber laser with galvo scanning delivers fast sintering and consistent energy distribution for dense nylon parts

-

End Use Part Capability

Produces durable functional components suitable for testing low volume production and final applications

-

IR Based Temperature Control

Advanced infrared monitoring maintains uniform thermal conditions across the powder bed

-

High Precision Recoater

Ensures smooth and even powder layers for repeatable part accuracy

-

No Support Structures Required

Enables complex geometries free moving assemblies and efficient nesting

-

Wide Material Compatibility

Optimized for nylon PA12 with support for additional SLS compatible powders

-

Intuitive Touch Interface

Seven inch touchscreen simplifies operation monitoring and job control

-

Low Waste and Energy Efficient

Unused powder can be reused reducing material loss and operating costs

-

Compact and Relocatable Design

Desktop form factor allows easy installation and relocation within workspaces

-

Cost Effective Industrial SLS

Enables multiple machine deployment and scalable manufacturing at lower investment

Material Compatibility

Nylon PA12 Powder

PA12 nylon powder is widely used in industrial selective laser sintering due to its strength and durability. It provides excellent mechanical performance for both prototype and production grade components. This material is ideal when high strength, precision and long term reliability are required across varied applications.

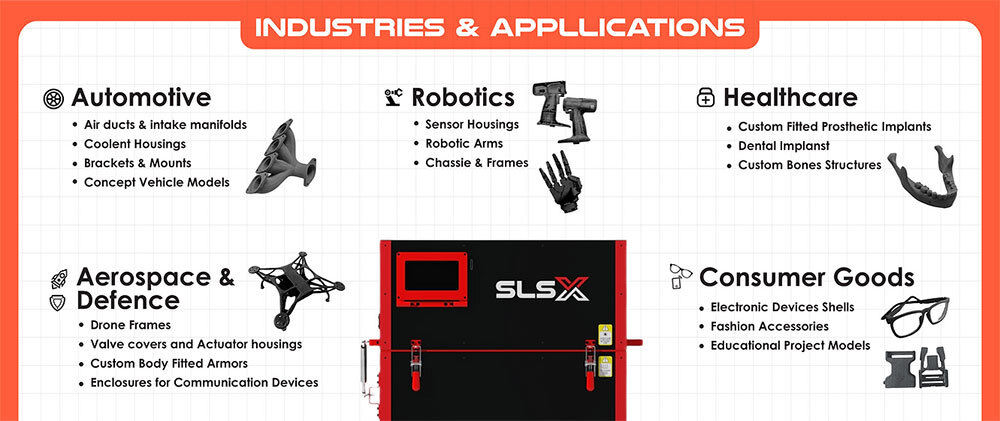

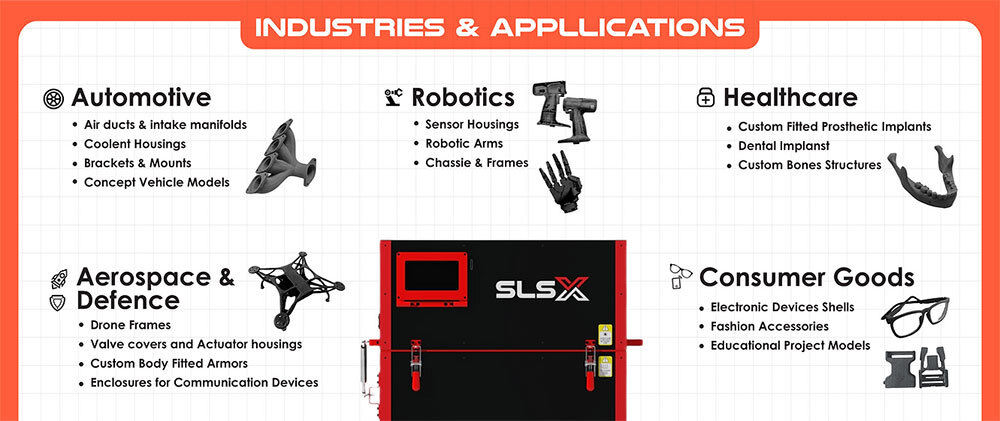

Industries and Applications

Aerospace and Defence

Lightweight Components- Production of durable lightweight parts supporting performance needs.

Complex Geometries- Manufacturing designs with internal channels or lattice structures.

End Use Parts- Frames and engineered features for demanding aerospace environments.

Automotive

Rapid Prototyping- Fast iteration cycles for complex automotive designs.

Durable Accessories- Suitable for custom mounts, brackets, knobs and interior components.

Robotics

Assembly Free Design- Creation of intricate components such as prosthetic hand mechanisms.

Gears and Actuators- High precision components with complex geometries.

Healthcare

Prosthetics and Implants- Custom-designed prosthetic components supporting comfort and mobility.

Sample Prototypes

What is SLS

Selective Laser Sintering is an additive manufacturing process that uses a laser to fuse nylon powder layer by layer into solid parts. The powder bed acts as natural support, allowing complex shapes high strength and production-ready components without design restrictions.