What Thermal Cameras Actually See: The Science Behind Infrared Imaging

Published by Tanuj Ahuja on 14th Sep 2025

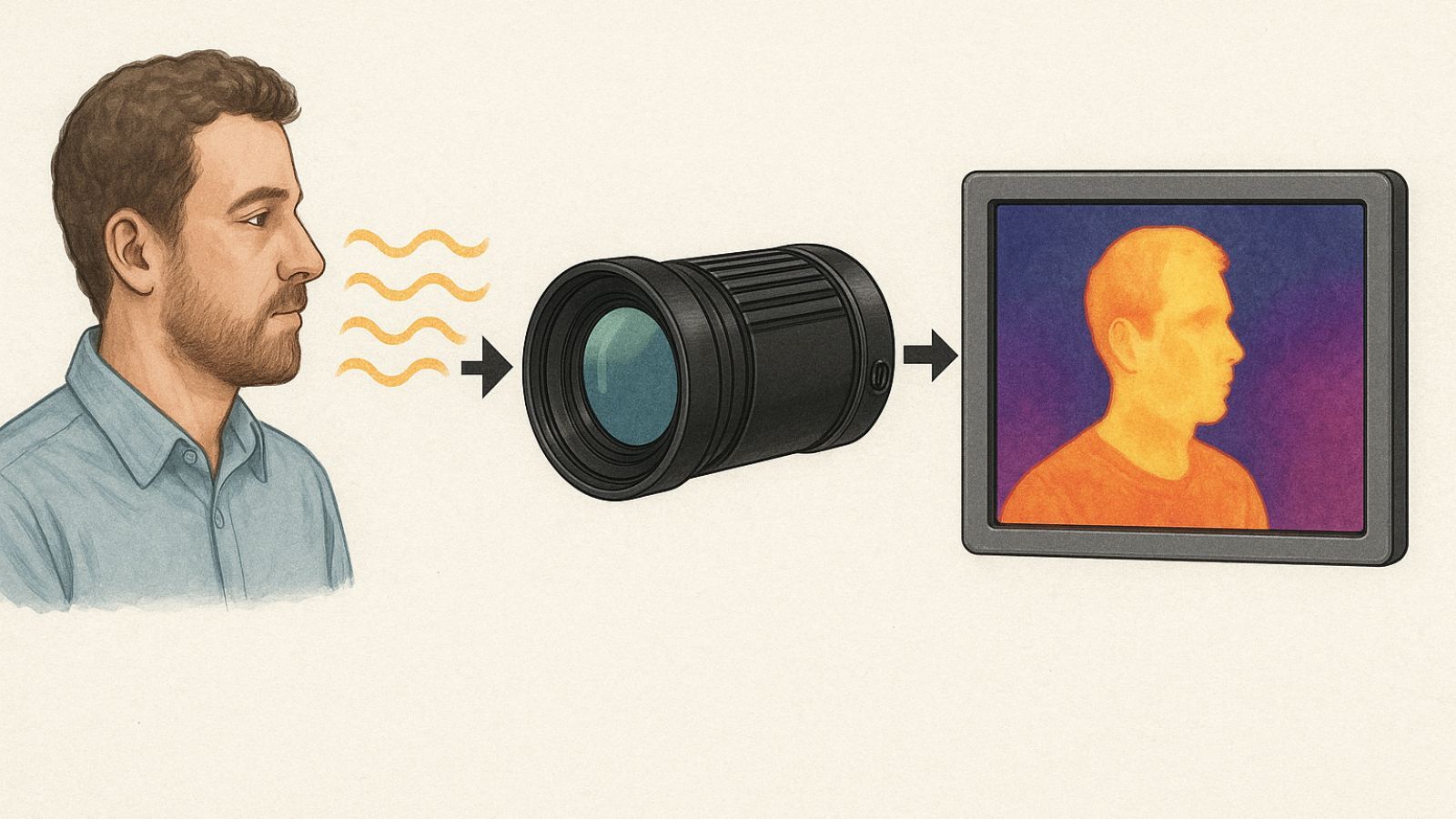

Thermal cameras can detect temperature differences as tiny as 0.02°C. These amazing devices let you see something your eyes can't - heat itself.

The cameras capture invisible infrared radiation that all objects above absolute zero emit and turn these heat signatures into visible images. Standard cameras need light to work, but thermal imaging works in total darkness, through smoke, and even behind certain barriers. This technology has become a great way to get insights in many fields. Since 1999, firefighters have saved countless lives by using these cameras to find victims in smoke-filled buildings. Building inspectors spot insulation problems easily, while maintenance teams can find overheating electrical systems before they fail completely.

The rise of infrared camera technology has been incredible since its military use in World War II. Modern thermal cameras come in various models - from simple 160×120 pixel versions to advanced systems reaching 1280×1024 pixels. Recent developments in machine learning and AI have substantially boosted what these cameras can analyze. A real-life example shows their value: one thermal camera found a smoldering hotspot in a grain storage facility and saved 75% of the stored crop.

This piece will show you exactly how thermal cameras work. You'll learn about the science of infrared radiation and how this technology continues to change industries from security and surveillance to medical diagnostics.

Infrared Radiation and Thermal Energy Explained

Every object around you releases thermal energy through infrared waves. Objects feel cold to touch but they constantly emit electromagnetic radiation. This energy movement creates the foundation for thermal cameras that detect infrared radiation from objects with temperatures above absolute zero (-273.15°C).

Black Body Radiation and Heat Emission

A blackbody concept helps explain how objects emit thermal radiation. This idealized physical object absorbs all electromagnetic radiation that hits it, whatever the frequency or angle. Perfect absorbers must also perfectly emit radiation when they reach thermal equilibrium - this follows Kirchhoff's radiation law. Planck's law determines the intensity and wavelength distribution of this emitted radiation based on the object's temperature.

The Stefan-Boltzmann law governs the total energy a blackbody emits. The power radiated per unit area equals the fourth power of its absolute temperature (P/A = σT⁴). This means an object radiates sixteen times more energy when its absolute temperature doubles. A kitchen oven at 600K radiates 16 times more power per unit area than objects at room temperature (300K).

Wien's displacement law shows that peak emission wavelengths become shorter as temperature rises (λₘₐₓT = 2.898×10⁻³ m·K). Room temperature objects emit radiation peaks in far infrared (8-25 μm). The sun's 6,000K surface emits radiation that peaks in the visible spectrum.

Emissivity Coefficients and Material Differences

Objects emit radiation differently. Emissivity measures how well an object emits infrared energy compared to a perfect blackbody. Values range from 0 (perfect reflector) to 1 (perfect blackbody). Most common materials fall between these values:

|

Material |

Emissivity Value |

|---|---|

|

Polished Aluminum |

0.05 |

|

Human Skin |

0.95-0.98 |

|

Paper |

0.93 |

|

Glass |

0.92 |

|

Water |

0.95 |

These emissivity differences explain why thermal cameras need adjustment for specific materials. Cameras show different apparent temperatures for objects at the same temperature unless properly adjusted. Materials like polished metals with high reflectivity reflect environmental infrared radiation and can cause measurement errors.

Why All Objects Emit Infrared Radiation

Thermal motion of atoms and molecules makes objects above absolute zero emit infrared radiation. Electric charges within materials oscillate and generate electromagnetic waves. Higher temperatures create more energetic molecular motion that leads to greater infrared emission.

Objects at the same temperature can emit different amounts of infrared radiation due to their emissivity properties. White paper emits more infrared heat than metal at the same temperature because paper has higher emissivity. Thermal cameras use these emission variations to create visible images of temperature differences across surfaces, making heat visible to human eyes.

How Thermal Cameras Convert Heat to Images

Converting invisible heat energy into visible imagery needs sophisticated technology inside every thermal camera. The experience from infrared radiation to the colorful thermal images you see involves multiple precise steps and components that work together.

Focal Plane Array Sensor Functionality

The focal plane array (FPA) sits at the core of every thermal camera - a grid of infrared-sensitive detector elements that works as the camera's "retina." Each pixel in this array captures infrared radiation through the camera's lens system independently. These detector elements convert thermal energy into measurable electrical signals, with numbers ranging from a few thousand to over a million pixels. A thermal camera's resolution directly links to the number of pixels in the FPA. High-end models can reach resolutions of 1280×1024 pixels.

Modern thermal cameras use two main types of FPAs. Cooled detectors need cryogenic cooling systems that reduce internal noise and achieve maximum sensitivity. These can detect temperature differences as small as 0.01°C. Materials like mercury cadmium telluride (MCT) or indium antimonide (InSb) make up these detectors. Uncooled detectors (often microbolometers) work at room temperature. They're more affordable and compact but slightly less sensitive. These typically use materials like vanadium oxide (VOx) that change electrical resistance when infrared radiation heats them.

Signal Processing and Color Mapping

The camera's processing electronics transform raw infrared data from the FPA into interpretable images. An analog-to-digital converter changes the detector's electrical signals into digital form. The digital processor applies several vital algorithms. These include non-uniformity correction to balance pixel-to-pixel sensitivity differences and faulty detector replacement that maintains image quality.

Each pixel gets colors or shades based on its detected temperature value. Individual pixels represent specific temperature data points in thermal imaging. The camera captures absolute temperature values, but the visual display depends on color mapping. Standard thermal cameras use either grayscale (brighter shades show warmer temperatures) or color palettes (reds, yellows, and whites indicate hotter areas, while blues and purples represent cooler regions).

Modern thermal cameras come with multiple palette options - Rainbow, Iron, Arctic, and Lava. It's worth mentioning that changing these palettes doesn't affect the underlying temperature data. The change only affects how that information appears visually. Users can adjust the temperature base and range to improve image clarity in specific applications.

Thermal Image vs Visible Light Image

Thermal images are nowhere near similar to visible light photography. Visible cameras detect reflected light in the 400-700 nanometer range. Thermal cameras capture emitted radiation in the much longer 7,000-14,000 nanometer range. This difference allows thermal cameras to:

-

Work independently of ambient lighting conditions

-

"See" through certain visual obscurants like smoke or light fog

-

Show temperature distributions instead of visual appearance

-

Operate using the object's own thermal emissions rather than reflected light

Thermal cameras make temperatures visible by converting infrared radiation intensity into visual contrast. The images display temperature distributions across surfaces instead of visual details. This explains the unique appearance of thermal images compared to traditional photographs - they map an entirely different property of the scene.

Standard cameras need sufficient ambient light and can't see in darkness. Thermal cameras detect heat signatures whatever the lighting conditions. These cameras can also reveal hidden issues like heat leaks in buildings or failing components in electrical systems that show no visible damage.

Types of Infrared Cameras and Their Components

Thermal cameras come in two main types based on their detector technology. Each type has its own advantages for different uses. The way these devices are built and what goes into them determines how well they work, their size, cost, and what they're best suited for.

Cooled vs Uncooled Detectors

Cooled thermal cameras use special detectors that are sealed in a vacuum. These detectors need to be cooled to extremely low temperatures - as low as 4K (-269°C). Most modern detectors work between 60K to 100K (-213°C to -173°C). The extreme cooling stops the detector from picking up its own infrared radiation. These cameras can detect tiny temperature changes - as small as 0.02°C in the best models. But they have some big drawbacks. They're expensive to buy and run. You need to wait several minutes for them to cool down before use. They also need maintenance after 10,000-13,000 hours of use.

Uncooled thermal cameras work at room temperature and are the most common type. These cameras are more affordable and compact. They can usually detect temperature differences of about 0.2°C. Since they don't need cooling systems, they start right away and use less power. They also need very little maintenance, which makes them perfect for everyday tasks like checking buildings and security monitoring.

Microbolometers and Sensor Arrays

Uncooled thermal cameras mostly use microbolometer technology. The main sensor has arrays of tiny elements that detect temperature. These arrays usually have thousands of individual pixels in layouts like 336×256 or 640×512. Each pixel in these focal plane arrays (FPAs) changes its electrical resistance when infrared radiation heats it up.

Manufacturers make microbolometer sensors using either vanadium oxide (VOx) or amorphous silicon (a-Si). These materials show measurable resistance changes when they absorb infrared energy. The camera turns these changes into thermal data. The pixels in uncooled detectors respond slowly - taking tens of milliseconds. A 1°C change in the scene only creates about a 0.03°C difference at the sensor.

Optical Systems and Display Units

Thermal cameras need special lenses that work with infrared wavelengths. These lenses are made from materials that let infrared radiation pass through, like germanium, silicon, and zinc selenide. Fixed lenses with different focal lengths (from 6mm to 100mm) help cameras work better at various distances and viewing angles.

The focal length determines what the camera can do. Longer focal lengths are better for seeing things far away, while shorter ones give you a wider view. The cameras also have processing units that turn detector readings into useful images through several steps.

Today's thermal cameras show these processed images on digital displays. Users can choose different color schemes, measurement tools, and temperature ranges. Advanced systems connect to computers through digital interfaces (like GigE Vision, I²C, or SPI) for more analysis and recording.

Thermal Camera Uses Across Industries

Thermal cameras serve practical purposes in medical clinics, industrial facilities, and many other sectors. These smart devices turn temperature differences into visual data. Professionals can spot problems that nobody can see with their naked eyes.

Building Inspections and Energy Audits

Energy auditors use thermal imaging to spot energy efficiency issues in buildings quickly. Thermal cameras show where insulation fails, air leaks, and moisture seeps in - all factors that waste energy. You can improve energy efficiency most affordably by sealing and insulating your building properly. The best results come when there's at least an 18°F temperature difference between inside and outside during inspections. Smart auditors combine thermal cameras with blower door tests. These tests create pressure differences that make air leaks stand out more clearly in thermal images.

Electrical and Mechanical Maintenance

Maintenance teams spot potential failures in electrical and mechanical systems with thermal cameras. They can identify overheating connections, overloaded circuits, and faulty parts before they cause major breakdowns. The cameras help check bearing temperatures in big motors, find steam trap failures, and see tank fluid levels in mechanical systems. Companies that regularly use thermal imaging for maintenance see less downtime, spend less on repairs, and their equipment lasts longer.

Medical and Veterinary Diagnostics

Healthcare settings benefit from thermal cameras as they offer safe, non-invasive imaging without radiation. Medical staff can detect inflammation, blood flow issues, and metabolic problems by looking at surface temperature patterns. Vets love these cameras because they can check animals quickly without causing stress. The technology works great for finding arthritis, damaged tendons, and laminitis in horses. It also helps monitor how well animals are doing and their stress levels.

Security, Surveillance, and Firefighting

Security teams rely on thermal cameras to catch intruders in dark or bad weather. Firefighters use special thermal devices to find their way through smoke and locate people who need help. Modern firefighting cameras come with cool features like Multi-Spectral Dynamic Imaging and Flexible Scene Enhancement that make structural details pop in thermal images. These tools help emergency teams track fires, find hot spots behind walls, and make smart decisions that save lives.

Limitations and Accuracy Challenges in Thermal Imaging

Thermal cameras are amazing tools, but they come with some key limitations that affect how well they work. These challenges shape how we read thermal images and use the data they give us.

Effect of Emissivity on Temperature Readings

The way materials emit infrared energy, called emissivity, plays a huge role in getting accurate measurements. Different materials have emissivity values from 0.01 to 0.99, where 1 means perfect emission. Shiny metals usually score below 0.10, while human skin and water reach about 0.98. Measurements become less reliable with materials scoring under 0.6. Most bare metals need special techniques because thermal cameras can't measure them accurately.

Wrong emissivity settings can throw off your readings badly. Temperature readings can be off by 20 degrees if the thermal image isn't focused right. Many professionals stick small pieces of electrical tape on reflective surfaces to fix this. They set the camera's emissivity to 0.95, which gives them readings within 2°C of accuracy.

Low Resolution and Frame Rate Constraints

Regular cameras beat thermal cameras by a lot when it comes to resolution. This makes it hard to see small details. Agricultural researchers often can't use these cameras to look at individual plant parts - they can only see the whole plant. The cameras can't show temperature differences between a plant's leaves, stems, and flowers.

Frame rate tells us how many images the camera takes each second, measured in Hertz (Hz). Common options include:

-

9Hz cameras: Good for things that don't move much

-

30Hz/60Hz cameras: Better at tracking moving objects

Faster frame rates help track moving objects without blur, but slower ones struggle with quick movements. Better performance means higher costs and more data to process.

Depth Perception and Reflective Surfaces

Thermal images show everything in 2D, with a fixed view and focus length. This makes it tough to judge depth, which affects how well you can spot hazards and move around. Objects at the same temperature look the same color or shade, which makes details harder to spot.

Shiny surfaces are tricky because they act like mirrors for infrared radiation. Mirrors, polished metals, glass, and ceramic tiles create what we call "thermal lies" - reflections that mess up temperature readings. Water causes problems too. Temperature differences can make it look like there are holes in floors. These readings aren't showing the actual surface temperature - they're just picking up reflections from nearby objects.

Conclusion

Thermal imaging technology turns invisible heat energy into visual data that helps people in a variety of fields. The technology lets us see how thermal cameras pick up infrared radiation that objects naturally give off when they're above absolute zero. These cameras turn heat patterns into images we can understand. The science behind it all - from blackbody radiation to changes in emissivity - shows complex physics at work in tools we use every day. The technology works thanks to key parts like focal plane arrays, and users can choose between cooled and uncooled detector systems based on their needs.

Thermal cameras have changed how work gets done in many industries. Firefighters can spot people through thick smoke. Building inspectors find places where energy escapes. Maintenance teams catch equipment problems before they happen. Medical staff can spot inflammation. These examples show why more people want to use thermal imaging technology. The cameras do have their limits though. Users need to know about emissivity issues, resolution limits, and problems with reflective surfaces to get accurate results.

The technology's future looks promising. Manufacturers are building better sensors with higher resolution, making more affordable options for consumers, and creating smarter analysis software. Whether you're a professional who uses thermal cameras or someone who loves the technology, knowing what these tools can and can't do helps you get the most out of them. Thermal imaging stands out as one of today's most flexible sensing technologies. It makes heat visible and gives us valuable insights in countless ways.

FAQs

Q. How do thermal cameras capture images?

A. Thermal cameras detect infrared radiation emitted by objects above absolute zero. They use specialized sensors to convert this heat energy into electrical signals, which are then processed to create visible images representing temperature differences across surfaces.

Q. What can thermal cameras see that regular cameras can't?

A. Thermal cameras can detect heat signatures invisible to the naked eye. They can see through darkness, light fog, and some materials, allowing them to identify temperature variations, energy leaks, and overheating components that standard cameras cannot capture.

Q. What are the main applications of thermal imaging technology?

A. Thermal cameras are used across various industries. They assist in building inspections for energy efficiency, electrical and mechanical maintenance to prevent equipment failures, medical and veterinary diagnostics for detecting inflammation, and in security and firefighting for navigation in low-visibility conditions.

Q. What are the limitations of thermal cameras?

A. Thermal cameras face challenges such as emissivity variations affecting temperature readings, lower resolution compared to visible light cameras, and difficulties with depth perception and reflective surfaces. These factors can impact measurement accuracy and image interpretation.

Q. How do cooled and uncooled thermal cameras differ?

A. Cooled thermal cameras offer higher sensitivity and can detect minute temperature differences, but they're expensive and require maintenance. Uncooled cameras are more affordable, compact, and widely used for everyday applications, though they have slightly lower sensitivity compared to cooled systems.