The Ultimate Guide to Connectors: Types and Uses

Published by Mayank Agrawal on 22nd Nov 2024

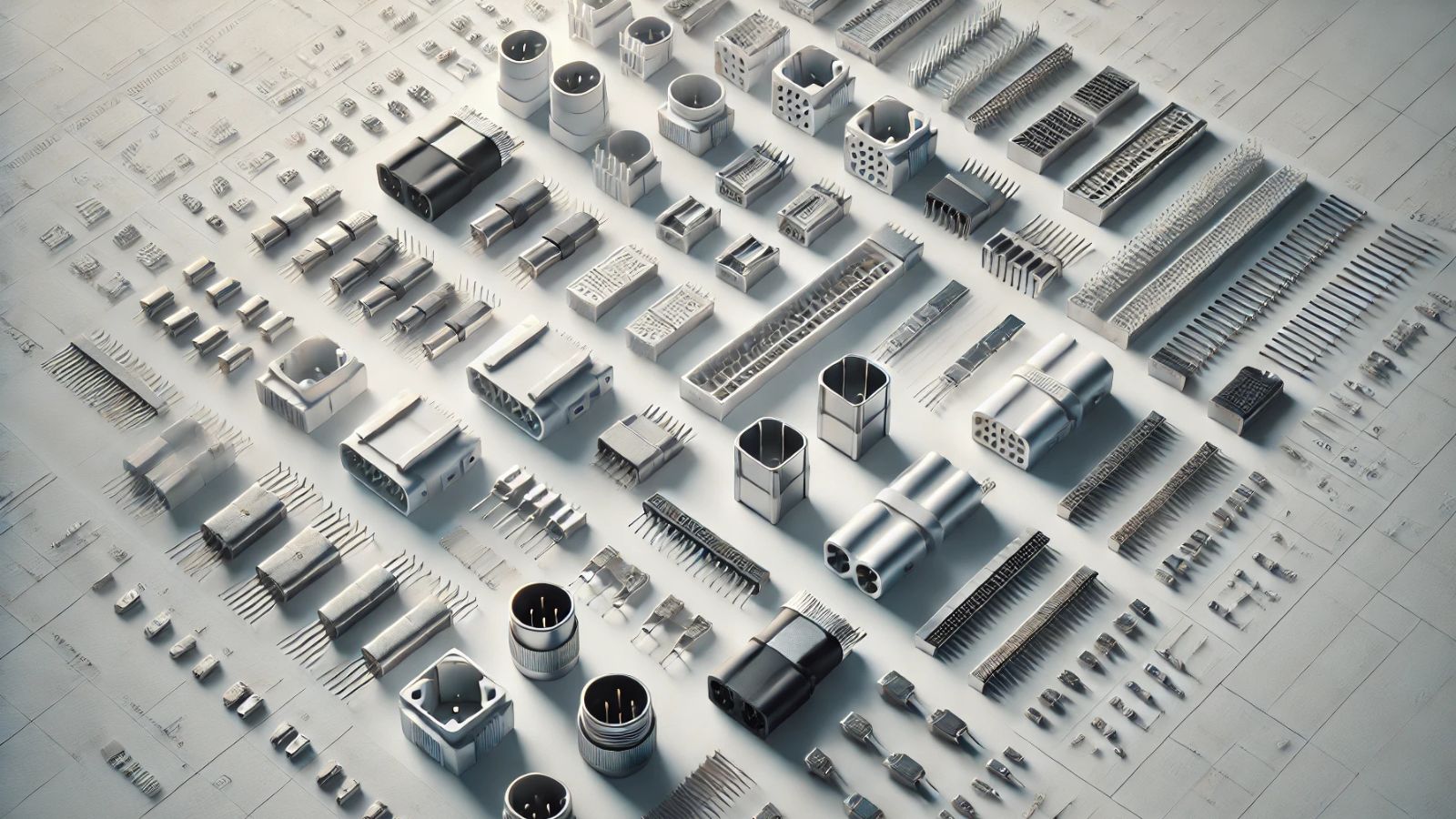

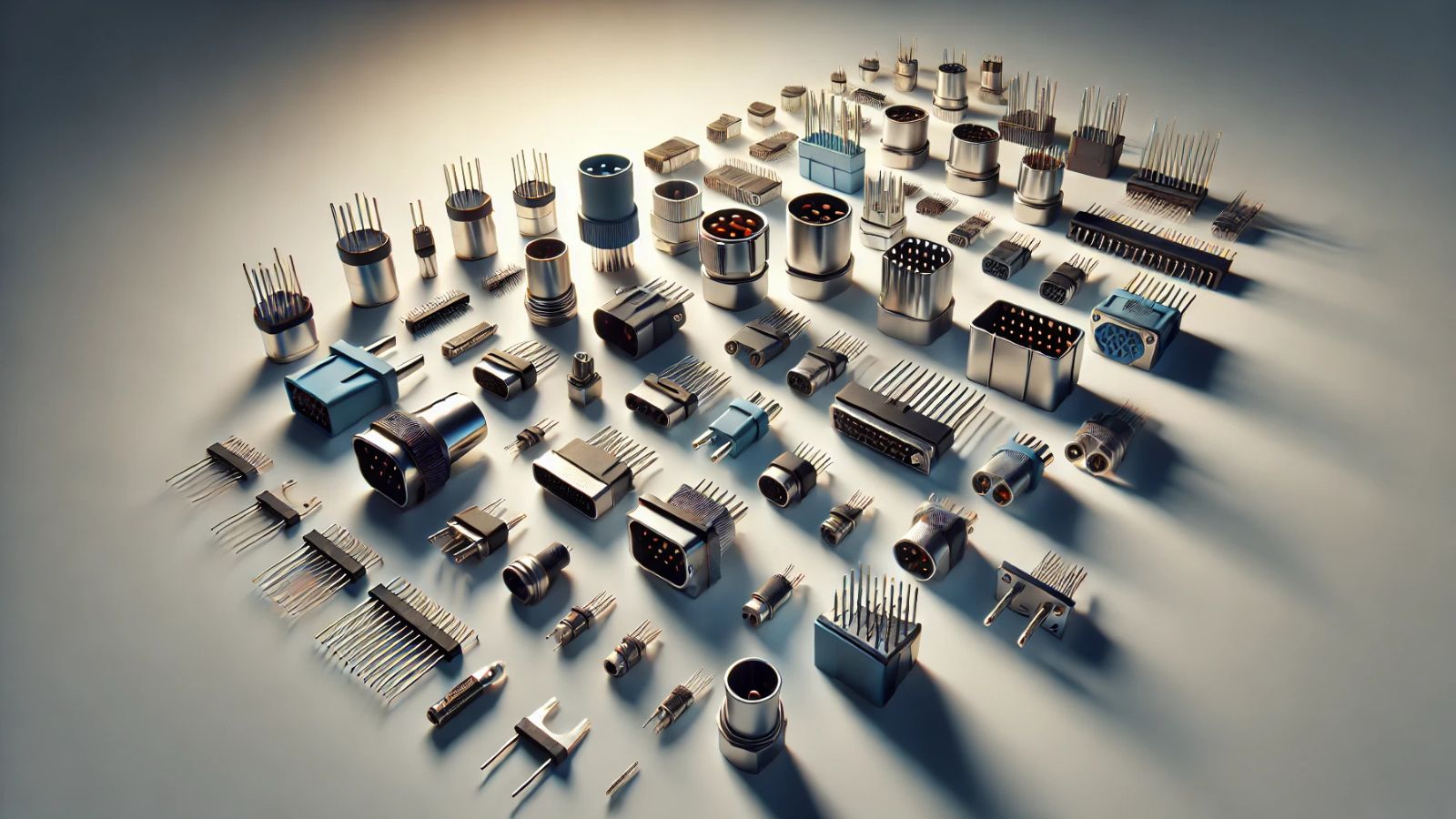

In the world of technology and engineering, connectors play a crucial role in linking various components and systems. These small but essential devices have a significant impact on data transmission, electrical connections, and overall system performance. From the ubiquitous USB connectors in our everyday devices to specialized PCB connectors in complex electronics, the range and application of connectors are vast and diverse.

This guide delves into the realm of connectors, exploring their types and uses across different industries. It covers the basics of connector technology, examines various connector types including RJ45 connectors, wire connectors, and automotive connectors, and provides insights on choosing the right connector for specific applications. Whether you're working with cable connectors, electrical connectors, or board-to-board connectors, understanding the nuances of different connector types is key to ensuring optimal performance and reliability in your projects.

Understanding Connector Basics

Explore the essentials of connectors, covering types, functions, and applications. Gain insights into how connectors enable efficient data, power, and signal transfer across devices, crucial for reliable performance in electronics, automotive, and industrial systems.

What are Connectors?

Connectors are essential coupling devices that join electrical terminations to create electrical circuits. These components enable contact between wires, cables, printed circuit boards, and electronic components. Connectors play a crucial role in transmitting data, power, and signals reliably, even in the harshest environments and under extreme conditions.

The world of connectors is vast and diverse, encompassing various types such as RJ45 connectors, wire connectors, and USB connectors. Each type serves a specific purpose in different applications, from everyday consumer electronics to complex industrial systems. For instance, RJ45 connectors are commonly used in computers and networking equipment to terminate Ethernet cables, while automotive connectors are designed to withstand the harsh conditions of highway and off-road transportation.

Key Components of Connectors

Connectors consist of several critical components that work together to ensure reliable electrical connections:

- Contacts: These are the metal parts that make the actual electrical connection. They can be male (pins) or female (sockets).

- Housing: This is the insulating body that holds the contacts in place and provides mechanical protection.

- Locking mechanism: Many connectors feature a locking system to prevent accidental disconnection.

- Shielding: Some connectors include shielding to protect against electromagnetic interference (EMI).

- Seals: In waterproof or environmentally sealed connectors, seals prevent the ingress of moisture and contaminants.

The design and materials used in these components vary depending on the connector's intended application. For example, connectors used in automotive or industrial settings often feature robust housings and seals to withstand harsh environments, while those used in consumer electronics may prioritize compact size and ease of use.

Importance in Electronics

Connectors play a vital role in modern electronics, serving as the backbone of connectivity in various systems. Their importance can be understood through several key aspects:

- Facilitating modular design: Connectors allow for the creation of modular systems, where components can be easily connected, disconnected, and replaced. This modularity is crucial in industries such as automotive, aerospace, and consumer electronics.

- Enabling data transmission: With the increasing demand for high-speed data transmission, connectors have evolved to support higher bandwidths. For instance, some modern connectors can handle data rates up to 112 Gbps, meeting the requirements of cutting-edge technologies.

- Power distribution: Connectors are essential for distributing power throughout electronic systems. High-voltage connectors, for example, are crucial in electric vehicles for transmitting power from the battery to the powertrain or electric motor.

- Size reduction: As electronic devices become smaller and more compact, connectors have adapted to reduce application size while maintaining or even improving performance. This trend is evident in the evolution of USB connectors, from the larger Type-A to the compact and reversible Type-C.

- Reliability in harsh environments: In industries such as aerospace and industrial automation, connectors must maintain reliable connections despite exposure to vibration, extreme temperatures, and other challenging conditions.

- Customization and versatility: The wide range of connector types available allows engineers to choose the best solution for their specific application. From board-to-board connectors in compact devices to cable connectors in large-scale industrial systems, there's a connector type for virtually every need.

Understanding the basics of connectors is crucial for engineers and technicians working in electronics and related fields. As technology continues to advance, connectors will undoubtedly evolve to meet the changing demands of various industries, ensuring reliable and efficient connections in the devices and systems of the future.

Types of Connectors

Connectors come in a wide variety of types, each designed for specific applications and environments. This diversity allows engineers and technicians to choose the most suitable connector for their particular needs. Let's explore some of the main categories of connectors and their uses.

Electrical Connectors

Electrical connectors are the backbone of many electronic systems, providing essential connections for power and signal transmission. These connectors come in various shapes and sizes, from simple wire connectors to complex multi-pin connectors.

Wire connectors, for instance, are used to join two or more electrical wires together. They come in different types, such as twist-on wire connectors (wire nuts), crimp connectors, and insulation displacement connectors (IDCs). These connectors are essential in both residential and industrial wiring applications.

Another crucial type is the PCB connector, which is used to connect printed circuit boards to other components or boards. These connectors can be surface-mounted or through-hole and are available in various pin configurations to suit different PCB layouts.

Data Connectors

In our increasingly connected world, data connectors play a vital role in transmitting information between devices. One of the most ubiquitous data connectors is the RJ45 connector, which is used for Ethernet connections in computer networks. These connectors terminate Ethernet cables and can connect to PCBs in three ways: surface mount, through-hole press-fit, and through-hole solder.

USB connectors are another type of data connector that has become nearly universal in consumer electronics. There are several types of USB connectors, including the older USB-A and micro-USB, as well as the newer USB-C. USB-C connectors are becoming increasingly popular due to their reversible design and ability to handle both power and high-speed data transmission.

Audio/Video Connectors

Audio and video connectors are specialized types designed to transmit audio and video signals. Common audio connectors include the 3.5mm headphone jack, RCA connectors, and XLR connectors used in professional audio equipment.

For video, connectors like HDMI, DisplayPort, and VGA are widely used in consumer electronics and computer monitors. These connectors are designed to handle high-bandwidth video signals and, in some cases, audio as well.

Automotive Connectors

The automotive industry relies heavily on specialized connectors that can withstand harsh conditions. Automotive connectors are built to endure extreme temperatures, vibrations, and exposure to various fluids and chemicals.

These connectors are used in various systems within vehicles, from engine control units to infotainment systems. They often feature robust locking mechanisms and seals to ensure reliable connections even in challenging environments.

One example is the DEUTSCH DMC-M Series connectors, which are used in commercial aircraft. These connectors enable critical data flows for high-speed internet access, in-flight entertainment technology, and navigation systems.

In the realm of electric vehicles, high-voltage connectors play a crucial role. These connectors transmit high-voltage power from the battery to the powertrain or electric motor, while miniature connectors are used for signal transmission in various vehicle systems.

As technology continues to advance, new types of connectors are being developed to meet emerging needs. For instance, the M8/M12 Connector System is engineered for machine industrial automation and control applications. This system provides a solution for the increasing demand for sensor connections that ensure safe and reliable communication in industrial environments.

The world of connectors is vast and continually evolving. From simple wire connectors to complex high-speed data transmission connectors, each type plays a crucial role in our interconnected world. As technology progresses, we can expect to see even more specialized and efficient connector types emerge, further enhancing our ability to connect and communicate in both personal and professional spheres.

Choosing the Right Connector

Selecting the appropriate connector for a specific application is crucial for ensuring optimal performance, reliability, and longevity of electrical and electronic systems. The process involves considering various factors and requirements unique to each project. Let's explore the key aspects to keep in mind when choosing connectors.

Factors to Consider

When selecting connectors, engineers and designers must take into account several critical factors:

- Electrical requirements: This includes voltage, current, and signal type. For instance, high-voltage connectors used in electric vehicles must handle power transmission from the battery to the powertrain, while miniature connectors are suitable for signal transmission.

- Size and form factor: The physical dimensions of the connector should be compatible with the available space in the application. For example, USB-C connectors are popular due to their compact size and reversible design.

- Number of contacts: Connectors come with varying numbers of pins or sockets, ranging from simple two-pin designs to complex multi-pin configurations with thousands of contacts.

- Mating cycles: Consider how frequently the connector will be mated and unmated throughout its lifetime. Some connectors, like those used in consumer electronics, may require thousands of mating cycles.

- Data transmission rates: For applications involving high-speed data transfer, such as computer networks or telecommunications equipment, connectors must support the required bandwidth. RJ45 connectors, for instance, are commonly used for Ethernet connections and can support data rates up to 10 Gbps.

Durability and reliability: Connectors should withstand the expected mechanical stresses, including vibration, shock, and insertion forces.

Application-Specific Requirements

Different industries and applications have unique connector requirements:

- Automotive: Connectors in this field must withstand harsh conditions, including extreme temperatures, vibrations, and exposure to fluids. Automotive connectors often feature robust locking mechanisms and seals to ensure reliable connections.

- Aerospace: In commercial aircraft, connectors like the DEUTSCH DMC-M Series enable critical data flows for high-speed internet access, in-flight entertainment, and navigation systems. These connectors must meet stringent safety and reliability standards.

- Industrial automation: The M8/M12 Connector System is engineered for machine industrial automation and control applications. It provides a compact, reliable connection system with environmental protection and supports bandwidth requirements up to 10 Gb/s.

- Consumer electronics: USB connectors, audio jacks, and HDMI connectors are common in this sector. These connectors need to be user-friendly, durable, and capable of supporting various data and signal types.

- Telecommunications: High-speed backplane connectors, such as the STRADA Whisper series, are designed for data transmission rates up to 112 Gbps, catering to the increasing bandwidth demands of modern communication systems.

Environmental Considerations

The operating environment plays a crucial role in connector selection:

- Temperature range: Connectors must function reliably within the expected temperature range of the application. Automotive connectors, for example, need to withstand both extreme cold and heat.

- Moisture and dust protection: In outdoor or industrial applications, connectors may require specific Ingress Protection (IP) ratings. For instance, some connectors offer IP67 or IP68 ratings for waterproof and dustproof performance.

- Chemical resistance: In certain industries, connectors may be exposed to various chemicals or solvents. The materials used in the connector construction should be resistant to these substances.

- Electromagnetic Interference (EMI): In sensitive electronic applications, shielded connectors may be necessary to prevent electromagnetic interference. Audio and visual connectors often feature enhanced EMI shielding.

- Vibration and shock resistance: Applications in transportation, aerospace, or industrial settings may subject connectors to significant mechanical stresses. Connectors for these environments should be designed to maintain reliable connections under such conditions.

By carefully considering these factors, application-specific requirements, and environmental conditions, engineers can select the most suitable connectors for their projects, ensuring optimal performance and longevity of their electrical and electronic systems.

Conclusion

Connectors have a significant influence on the world of technology and engineering, serving as crucial links between various components and systems. From everyday USB connectors to specialized automotive connectors, these devices play a key role in data transmission, electrical connections, and overall system performance. The wide range of connector types available allows engineers to choose the best solution to suit their specific needs, whether they're working with cable connectors, electrical connectors, or board-to-board connectors.

To select the right connector, it's essential to consider factors such as electrical requirements, size, durability, and environmental conditions. This consideration ensures optimal performance and reliability in diverse applications, from consumer electronics to industrial automation. As technology continues to advance, we can expect to see new and improved connector types emerge, further enhancing our ability to connect and communicate in both personal and professional spheres.

FAQs

Q. What are connectors and what are their types?

A. Connectors are classified into various types based on their termination ends, which include board-to-board connectors, cable/wire-to-cable/wire connectors, and cable/wire-to-board connectors. Typically, these connectors are involved in six different levels of interconnection.

Q. What is the purpose of using connectors?

A. Connectors are essential for linking two separate entities in electronics, enabling them to form a larger circuit. They play a crucial role in both creating and facilitating various types of electrical connections.

Q. How are connectors utilized in computers?

A. In computing, connectors are used to interface with other devices, allowing for data exchange. For instance, USB connectors enable the connection between devices and computers, while audio connectors link speakers and headphones. Connectors also support the modularity of electronic components, allowing for easy assembly and disassembly.

Q. What role do connectors play in electronics?

A. In the realm of electronics, connectors serve as electromechanical devices that establish electrical connections between different parts of an electrical circuit, or across multiple circuits. This integration helps in forming a cohesive and larger circuit.