How Magnetic Sensors Actually Work: From Basic Principles to Real Applications

Published by Sumit Chawla on 20th Sep 2025

The most sensitive magnetic sensor can detect fields so tiny that it measures magnetic signals from your heart and brain. These sensors work by detecting magnetism from magnets or electric currents. They turn invisible magnetic fields into electrical signals we can measure.

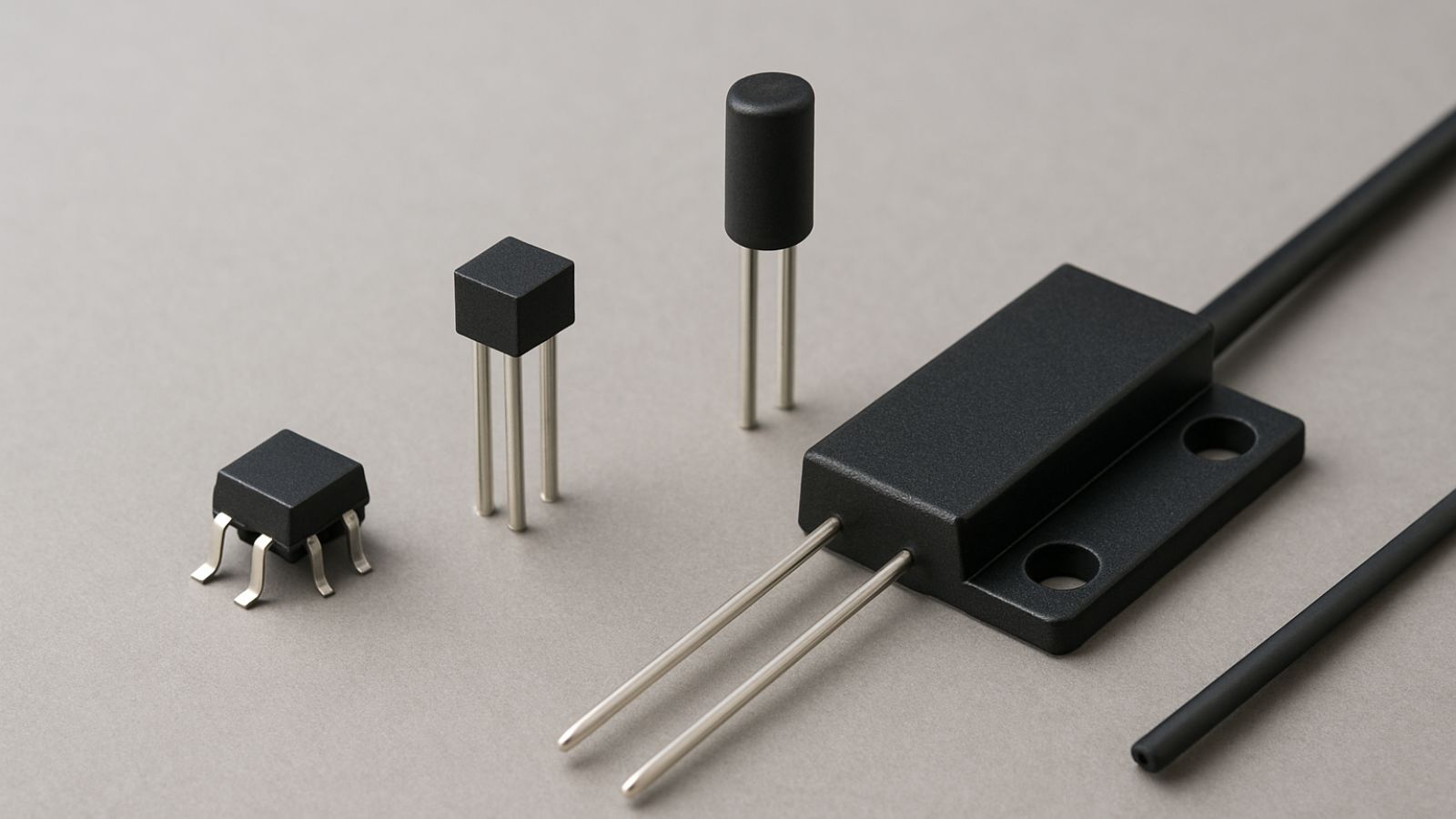

Magnetic sensors come in many shapes and sizes. Each type uses different physical effects to work well. Simple coils and reed switches work alongside sophisticated Hall elements and magnetoresistive components. These sensors give unique capabilities for different uses. Some advanced sensors that use the Tunnel Magneto-Resistive (TMR) effect are a big deal as it means that their sensitivity ratios go beyond 100%. This makes them perfect for tasks needing extreme precision. Your smartphone knows its orientation and your car's anti-lock brakes work smoothly thanks to these magnetic sensors.

This piece explains how different magnetic sensors work - from simple physical principles to real-world uses. The story starts with Hall effect sensors (found in 1879) and goes up to state-of-the-art MEMS magnetic field sensors with amazing spatial resolution. Recent advances have substantially increased sensor sensitivity by combining magnetic alloy layers with silver nanolayers. Understanding these devices' basic principles helps you learn about how they reshape the scene in automotive, industrial automation, consumer electronics, and medical equipment industries.

Fundamentals of Magnetic Field Sensing

Magnetic fields exist everywhere around us—from Earth's natural field to those your home electrical devices create. The way these invisible forces interact with materials and electric charges creates the foundation for all magnetic sensing technologies.

Magnetic Flux Density and Lorentz Force Basics

The tesla (T) serves as the standard unit for magnetic flux density (B-field), which measures magnetic field intensity. A charged particle moving through a magnetic field experiences a force perpendicular to its velocity and the magnetic field direction. Scientists call this the Lorentz force, which stands as the key principle behind magnetic field detection. The formula F = qvB sin(θ) explains this interaction. Here, F shows force magnitude, q represents particle charge, v stands for velocity, B indicates magnetic flux density, and θ denotes the angle between velocity and magnetic field vectors.

The B-field strength changes based on two main factors: how far you are from the source and the current strength in the field-generating conductor. This relationship helps engineers position magnetic sensors at strategic points near measured objects. The magnetic field around a current-carrying wire follows the right-hand rule, which creates circular field lines that change direction based on current flow.

Induction vs Magnetoresistance: Core Physical Effects

Scientists use two main physical mechanisms for magnetic field sensing: magnetic induction and magnetoresistance. Each method shines in specific applications.

Magnetic induction sensors work on Faraday's law principles, where changing magnetic fields create electromotive force (emf) in conductors. A magnet approaching a coil increases magnetic flux density and generates opposing forces that produce induced current. The coil's output voltage shows the rate of magnetic field change rather than its absolute value. This makes induction sensors great at detecting moving magnetic objects but less effective with static fields.

Magnetoresistance (MR) sensors work differently. They detect magnetic fields by measuring resistance changes in materials exposed to magnetic fields. Scientists found this MR effect in ferromagnetic materials like iron and nickel, where electron scattering patterns shift under magnetic influence. Three main types exist with different sensitivity levels:

-

Anisotropic Magnetoresistive (AMR) sensors: These use resistance changes in ferromagnetic thin films

-

Giant Magnetoresistive (GMR) sensors: They rely on alternating ferromagnetic and non-magnetic layers

-

Tunnel Magnetoresistive (TMR) sensors: These use quantum tunneling effects between magnetic layers

Magnetoresistive sensors usually perform better than induction sensors, offering higher sensitivity and accuracy because they produce less noise. MR sensors can measure static magnetic fields directly, while induction-based technology needs field changes or sensor movement to generate signals.

Both technologies keep evolving. MR sensors excel in high-precision tasks like lateral flow immunoassay and microfluidic biochips. Induction sensors remain popular where simplicity, flexibility, and non-contact operation matter most.

Types of Magnetic Sensors and Their Operating Principles

Magnetic sensors have come a long way through several technological generations. Each generation uses different physical effects to detect and measure magnetic fields. The evolution ranges from basic coil designs to complex quantum tunneling effects. Understanding how each type works helps choose the right sensor for specific uses.

Coil-Based Magnetic Pickup Sensor Working Principle

The magnetic pickup sensor is one of the most basic sensing technologies. It has a permanent magnet, pole-piece, and sensing coil inside a cylindrical case. A ferromagnetic object (target) passing near the pole-piece changes the magnetic flux field through the sensing coil. This change creates a signal voltage that depends on the target's size, speed, and how close it is. The signal's polarity changes as the target moves toward or away from the pole-piece. These sensors work great at detecting gear teeth, sprockets, or other moving machine-mounted targets. The output voltage matches the speed directly.

Hall Effect Sensor: Static Field Detection

Hall effect sensors can detect static magnetic fields without any movement, unlike induction sensors. These sensors create a voltage when a magnetic field crosses a semiconductor plate perpendicular to current flow. Moving electrons get pushed by the Lorentz force, which creates a Hall voltage perpendicular to both current and magnetic field. The voltage matches the field strength, allowing direct measurement. Most Hall sensors include amplification circuits and voltage regulators. These additions make them more sensitive and stable even when supply voltages change.

Magnetoresistive Sensors: AMR, GMR, and TMR Explained

Magnetoresistive sensors find magnetic fields through resistance changes in materials. There are three main types, each more sensitive than the last:

-

AMR (Anisotropic Magnetoresistance) sensors use single-layer ferromagnetic materials with MR ratios around 5%

-

GMR (Giant Magnetoresistance) sensors use alternating ferromagnetic and non-magnetic layers with MR ratios near 20%

-

TMR (Tunnel Magnetoresistance) sensors use quantum tunneling effects with insulating layers between magnetic layers. Their MR ratios are a big deal as it means that they exceed 100%

TMR sensors produce signals about 20 times stronger than AMR and 6 times stronger than GMR sensors. This makes them perfect for high-precision tasks.

Reed Switches and Their Contact-Based Operation

Reed switches have a straightforward but effective contact-based design. They contain ferromagnetic metal reeds sealed in a glass tube with a small gap between them. The reeds become magnetized when a magnetic field comes near. They attract each other and touch, closing an electrical circuit. The sealed design protects against dust, dirt, and explosive environments. These switches can work for billions of cycles before failing. Security systems often use them to trigger alarms when door or window magnets move away from the sensor.

MEMS Magnetic Sensors Using Lorentz Force

MEMS (Microelectromechanical Systems) magnetic sensors work with tiny resonant structures that react to magnetic fields through the Lorentz force principle. These sensors have micromachined resonant elements that get excited when current flow meets magnetic fields. The movement can be measured through optical, piezoresistive, or capacitive methods and matches the magnetic field strength directly. These small sensors can measure a wide range of fields (from nanotesla to tesla) and are budget-friendly to make. This makes them great for portable electronics and biomedical uses.

Materials and Methods: Sensor Construction and Signal Processing

A magnetic sensor's performance depends on the materials used in its construction. The evolution of material selection and fabrication techniques has led to sensors that are more sensitive and work better in different settings.

Ferromagnetic Thin Films in MR Sensors

Ferromagnetic thin films are the foundations of magnetoresistive sensor technology. Most MR sensors use permalloy (typically 80% nickel and 20% iron alloy) on glass or silicon substrates as sensitive elements. These films change their electrical resistance when exposed to external magnetic fields. Engineers carefully control the film's thickness and composition during fabrication to get the best performance. Advanced designs use multiple layers—alternating between ferromagnetic and non-magnetic—to boost sensitivity. Modern TMR sensors are a big deal as it means that their MR ratios exceed 100%, which makes them far more sensitive than previous versions.

Semiconductor Layers in Hall Elements

The core sensing element in Hall effect sensors consists of thin semiconductor layers. Silicon remains the popular choice because it's cheap and works well with standard semiconductor manufacturing processes. GaAs offers better performance with electron mobility of approximately 8500 cm²/(V·s), compared to silicon's 1300 cm²/(V·s). This higher mobility helps GaAs-based Hall sensors achieve greater sensitivity with better temperature stability (typical value of -0.04% K⁻¹). Indium antimonide (InSb) sensors show even higher sensitivity but struggle with temperature characteristics.

Ion implantation plays a crucial role in Hall sensor fabrication. The process starts with implanting phosphorus ions into silicon substrates and annealing them to restore crystalline structure. Gold wires, deposited through electron beam evaporation, create the electrical leads.

Signal Conditioning Circuits for Magnetic Sensors

Raw magnetic sensor outputs need processing to become useful measurements. Signal conditioning circuits include:

-

Amplification stages that boost weak Hall voltages or small resistance changes from MR elements

-

Filtering components that clean up noise and improve signal quality

-

Linearization circuits that fix non-linear sensor responses

Hall effect sensors usually come with built-in differential amplifiers that deliver high input impedance and excellent noise rejection. Specialized integrated circuits in closed-loop current sensors handle magnetic field probe excitation, signal conditioning, and compensation coil driver functions. These integrated solutions feature temperature compensation to reduce drift, along with auto-zero techniques that ensure excellent DC stability and accuracy.

Performance Metrics and Calibration Techniques

A magnetic sensor's capabilities depend on several core performance parameters. These metrics help determine if a sensor suits specific applications and affect its measurement accuracy in real-life environments.

Sensitivity, Linearity, and Hysteresis in Sensor Output

Sensitivity shows the relationship between output and input signals. Sensors with higher sensitivity work better at detecting weak magnetic fields. The sensitivity constant should stay stable no matter what field strength is measured. The actual value often changes with field magnitude, which affects how linear the measurements are. Optical fiber magnetic field sensors reach impressive sensitivity values of 757.1 pm/Oe and can detect ranges of 50–200 Oe.

Linearity measures how well the output signal matches changes in the input signal. Hall-based sensors achieve linearity errors that are nowhere near ±0.25% full scale (±5mV) within their normal output range (10-90% VDD). Linearity errors grow larger outside this range because of electrical saturation effects. Magnetoresistive sensors need calibration or feedback correction mechanisms to deal with non-linearities.

Hysteresis describes how a sensor's magnetization curve doesn't retrace its path exactly. A hysteresis loop forms as ferromagnetic materials go through magnetization and demagnetization cycles. Sensors with lower hysteresis give more consistent and accurate measurements. The air gap size has an inverse relationship with hysteresis in magnetic concentrator cores.

Noise Reduction Using Lock-in Amplifiers

Lock-in amplifiers (LIAs) excel at finding weak magnetic signals in noisy environments. These devices work in multiple stages. They first move the input signal's spectrum to a modulation frequency and amplify it. Next, they detect phase-sensitive information and filter out remaining noise through a low-pass system. This approach works particularly well to reduce 1/f noise effects at low frequencies.

LIAs can spot tiny signals hidden under large amounts of unrelated noise if they know the desired signal's frequency and phase. Modern analog LIAs achieve an impressive current sensitivity of 1 pA while using only 429.63 μW of power.

Zero-Point and Gain Calibration Methods

Proper calibration makes sure magnetic measurements match real field values. Zero-point calibration fixes sensor offset errors by measuring output without any field present and making needed corrections. Gain calibration handles scale-factor errors by comparing readings at known field strengths.

Most calibration methods fix the main linear time-invariant errors without special equipment. They can handle sensor bias/offset, scale-factor errors, cross-coupling inaccuracies, and soft/hard-iron distortions all at once. AMR sensors use advanced techniques like continuous reset-and-set operation modes to improve resolution. They also use amplitude or time measurement approaches to fix temperature-related issues.

Magnetic Sensor Applications Across Industries

You'll find magnetic sensors in almost every device you use daily. These sensors transform magnetic fields into practical data that powers control systems and user features in everything from your smartphone to industrial robots.

Magnetic Proximity Sensor Working Principle in Robotics

Magnetic proximity sensors in robotics use magnetoresistive elements to detect magnetic vector changes when objects come near. These sensors detect positions without contact at distances up to 60 mm, which makes them perfect for protected installation with flexibility. We used them to monitor final positions of telescopic outriggers and stroke limitations in hydraulic cylinders. Robots can detect objects without physical contact through these sensors. The magneto-resistive element responds only to magnetic fields and produces digital output signals that are ten times more sensitive than Hall elements. Robots can direct their movements effectively, detect heading, and control motion with high precision.

Magnetic Compass Sensor in Smartphones

Your smartphone contains three magnetic field sensors mounted at right angles to determine Magnetic North's direction. These sensors work with three accelerometers that detect gravity to provide complete orientation data. The phone's software calculates the correction angle between magnetic and true north based on your GPS location and a global declination angle map. Users in areas with large declination angles like California (~15°) or Brazil (>20°) would get lost quickly without this correction. This technology powers compass functionality, navigation, and augmented reality apps while using minimal power.

Current Sensing in Automotive Systems

Current sensors are vital components in modern automotive systems. You'll find them in electrified steering, braking, and powertrain components. Magnetic current sensors beat traditional methods with their smaller size, lower power use, and built-in isolation. These sensors monitor battery current flow in electric vehicles while ensuring safe operation even with strong electromagnetic interference. High-voltage charging systems at 400V or 800V need exact current measurements with isolation capabilities that magnetic sensors deliver easily.

Position Detection in Industrial Automation

Position sensors improve efficiency in industrial automation by measuring without contact and lasting longer. Factory settings need both linear and angular position sensing for complex motor movements that require precision and consistency. Magnetic position sensors work great in tough environments because dust, moisture, and oil don't affect them. They can detect through non-magnetic materials, which adds flexibility to robotics and automation technologies. These sensors provide the foundation for precise control and immediate feedback.

Limitations and Environmental Constraints

Magnetic sensors, even the most advanced ones, face operational challenges that can affect their accuracy and reliability. You can implement better countermeasures in your sensing applications by learning about these limitations.

Temperature Drift and Compensation Techniques

Temperature variation poses one of the biggest challenges to magnetic sensor accuracy. Every magnetic sensor reacts to temperature effects, though the impact varies by type. TMR sensors show both sensitivity drift and zero-point drift, with temperature drift coefficients reaching 985.39 ppm/°C without compensation. Temperature fluctuations reduce measurement repeatability, with root mean square errors as high as 0.84.

Engineers have developed two main approaches to tackle these challenges:

Hardware compensation uses components with temperature characteristics opposite to the sensor's natural response. This method is straightforward but offers limited precision and doesn't work well below 25°C.

Software compensation gives better flexibility and precision through algorithms that build temperature characteristic curves. All the same, this approach needs extra temperature sensors and processors that might slow down immediate performance. Both methods don't deal very well with poor repeatability in temperature drift characteristics.

LSTM networks now show promise in overcoming these limitations. These networks use multi-time scale input-output models to capture the connection between environmental temperature and sensor output bias.

Magnetic Interference and Shielding Requirements

Nearby conductors or equipment can create external magnetic fields that seriously distort magnetic sensor readings. Research shows that good shielding can cut down these effects by a lot.

The sensor plane and high-current conductors should line up perpendicular to each other to minimize interference. Keeping enough space between the sensor and current-carrying traces on PCBs helps reduce measurement errors.

Surface-mount magnetic alloy shields that cover the sensor package are a great way to shunt external magnetic flux away. Some extreme cases need dual shields on both PCB sides to provide complete protection against interference.

Conclusion

This complete exploration of magnetic sensors shows how devices turn invisible magnetic fields into measurable electrical signals. Magnetic sensors are the life-blood of modern electronics and industrial systems, from simple principles to ground applications.

These sensors work through different physical effects, and each offers unique advantages. Hall effect sensors detect static fields effectively. Magnetoresistive sensors deliver exceptional sensitivity. MEMS-based designs provide remarkable spatial resolution. The field keeps evolving from simple coil-based sensors to sophisticated TMR technologies. This is a big deal as it means that sensitivity has improved by more than 100% in modern designs.

Material choice shapes how these sensors perform. The physical construction directly influences sensitivity, linearity, and environmental resilience. This applies to ferromagnetic thin films in MR sensors and specialized semiconductor layers in Hall elements. Learning about these relationships helps you pick the right sensor that meets your needs.

Problems are systemic with magnetic sensors that need careful attention. Temperature drift affects measurement accuracy substantially. Hardware or software compensation techniques can reduce these effects. External magnetic interference needs proper shielding and positioning to maintain measurement integrity. Notwithstanding that, magnetic sensors have become common in everything from smartphone navigation to automotive safety systems.

These sensors' versatility keeps growing in industries of all sizes. Modern magnetic sensors started simple but now use sophisticated signal processing for remarkable sensitivity and accuracy. Advanced manufacturing techniques and new materials will lead to better sensor performance, smaller sizes, and improved power efficiency.

Magnetic sensors represent how physical principles create practical technologies that boost many aspects of modern life. The knowledge of magnetic sensor principles gives valuable insight into an essential part of our sensor-driven world, whether you develop new products or want to learn about everyday devices.

FAQs

Q. How do magnetic sensors detect magnetic fields?

A. Magnetic sensors use various physical effects to detect magnetic fields. Some sensors, like Hall effect sensors, produce a voltage when exposed to a magnetic field. Others, like magnetoresistive sensors, change their electrical resistance in response to magnetic fields. These changes are then converted into measurable electrical signals.

Q. What are the main types of magnetic sensors?

A. The main types of magnetic sensors include Hall effect sensors, magnetoresistive sensors (AMR, GMR, and TMR), coil-based magnetic pickup sensors, reed switches, and MEMS magnetic sensors. Each type has unique operating principles and is suited for different applications.

Q. How are magnetic sensors used in everyday devices?

A. Magnetic sensors are widely used in smartphones for compass and navigation functions, in automotive systems for current sensing and position detection, and in industrial automation for proximity sensing and position measurement. They're also found in security systems, robotics, and many other applications.

Q. What factors affect the accuracy of magnetic sensors?

A. The accuracy of magnetic sensors can be affected by temperature variations, which cause drift in sensor output. External magnetic interference from nearby electrical equipment or conductors can also distort readings. Additionally, factors like sensor linearity, hysteresis, and sensitivity play roles in overall accuracy.

Q. How are magnetic sensors improving over time?

A. Magnetic sensors are continually improving through advancements in materials and manufacturing techniques. Modern sensors, like those using the Tunnel Magnetoresistive (TMR) effect, can achieve sensitivity ratios exceeding 100%. Ongoing research focuses on enhancing sensitivity, reducing size, improving temperature stability, and developing better signal processing techniques.