Beginner’s Guide to Motor Drivers: Everything You Need to Know

Published by Sunil Kant on 3rd Oct 2024

Ever wondered how those cool robots and gadgets move so smoothly? The secret lies in a nifty device called a motor driver. This little powerhouse has a big impact on controlling various types of motors, from DC motors to servo motors and even stepper motors.

In this guide, we'll break down the basics of motor drivers and explore their different types. You'll get the lowdown on the H-Bridge circuit, which is at the heart of motor control. We'll also walk you through implementing motor control with Arduino, giving you hands-on experience with speed control and direction management. By the end, you'll have a solid grasp of how motor drivers work their magic in bringing motion to life.

Understanding Motor Driver Basics

Whether you're tinkering with a DIY project or diving into industrial automation, understanding motor drivers is key to making things spin, turn, and move with precision. This little powerhouse acts as a bridge between your microcontroller and the motor, making sure everything runs like clockwork.

How motor drivers work

Think of a motor driver as a translator. It takes the low-current signals from your microcontroller and beefs them up into high-current signals that can get your motor spinning. Why is this necessary? Well, your microcontroller is a bit of a lightweight when it comes to power, while motors are real energy hogs. The motor driver steps in to make sure everyone's speaking the same language.

Here's the cool part: motor drivers don't just amplify signals. They also give you control over your motor's speed, direction, and even torque. It's like having a remote control for your motor!

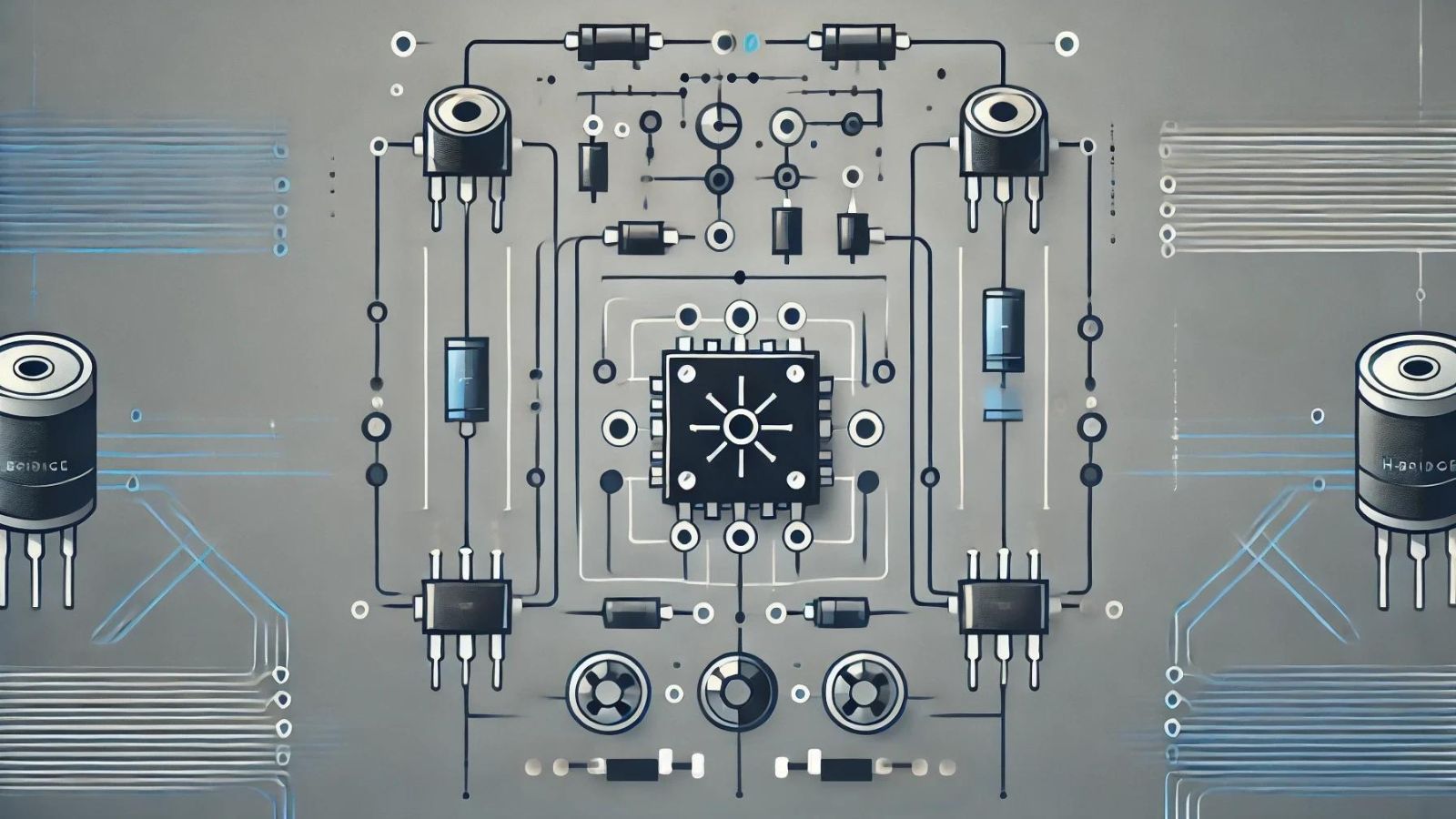

One of the most common setups you'll come across is the H-bridge circuit. Picture four switches arranged in an "H" shape. By flipping these switches in different combinations, you can make your motor spin forward, backward, or come to a stop. It's pretty neat stuff!

Now, you might be thinking, "That sounds complicated!" But don't worry. Many motor drivers come as integrated circuits (ICs) that package all this functionality into a single chip. This makes it much easier for you to get your motors up and running without having to build complex circuits from scratch.

Key components

Let's break down the main parts that make up a motor driver system:

- Controller: This is usually a microcontroller or microprocessor. It's the brains of the operation, sending out low-power control signals to tell the motor what to do.

- Motor Driver IC: This is where the magic happens. It takes those wimpy signals from the controller and turns them into robust commands that can actually drive the motor.

- Motor: This could be a DC motor, servo motor, or stepper motor. Each type has its own quirks and needs when it comes to control.

- Power Supply: This provides the juice needed to run both the driver circuitry and the motor itself. Make sure it matches what your setup requires!

- Protection Features: Many modern motor drivers come with built-in safeguards against things like overcurrent or overheating. These can be real lifesavers for your projects.

Some motor drivers also include fancy extras like communication interfaces (think SPI or CAN bus) that let you fine-tune your control and get feedback from the motor. This can be super helpful when you're working on more complex projects.

Remember, the key to choosing the right motor driver is understanding your specific needs. Consider factors like the type of motor you're using, how much power you need, and what kind of control you want over your motor's behavior. With the right motor driver in place, you'll be well on your way to creating smooth, precise movements in your robotics or automation projects!

Types of Motor Drivers

You'll find a variety of motor drivers out there, each designed to work with specific types of motors. Let's break down the main types you're likely to come across.

DC motor drivers

These are the workhorses of the motor driver world. DC motor drivers are perfect for controlling those trusty DC motors you see in so many projects. They take the AC power from your wall socket and convert it into the DC power your motor needs. What's cool about DC drivers is how they let you fine-tune your motor's speed. You can crank it up or slow it down with ease, giving you a wide range of control.

Stepper motor drivers

If precision is your game, stepper motor drivers are your best friend. These drivers work hand in hand with stepper motors to give you super accurate control over position and speed. They're like the conductors of a motor orchestra, sending out carefully timed pulses to make the motor move in tiny, precise steps. This makes them ideal for things like 3D printers or CNC machines where every little movement counts.

Servo motor drivers

Servo motors are all about quick, accurate movements, and servo drivers are what make that happen. These drivers take your input signals and turn them into the right kind of power to make servo motors zip to exactly where you want them. They're great for robotics or any project where you need speedy, precise control.

Brushless DC motor drivers

Last but not least, we've got brushless DC (BLDC) motor drivers. These are the high-tech cousins in the motor driver family. BLDC drivers work with brushless DC motors, which are known for their efficiency and long life. These drivers have to be pretty smart because they need to figure out the right timing to power the motor's coils. This makes them a bit more complex, but they're worth it for their smooth operation and energy efficiency.

Each type of motor driver has its own strengths, and choosing the right one depends on what kind of motor you're using and what you're trying to achieve. Whether you're looking for raw power, pinpoint accuracy, or energy efficiency, there's a motor driver out there that's perfect for your project. Just remember, matching the right driver to your motor is key to getting the best performance out of your setup.

H-Bridge Circuit: The Heart of Motor Control

You've probably heard about H-bridges if you've tinkered with motor control. This nifty circuit is the secret sauce behind making motors spin in both directions. Let's break it down and see why it's so crucial for controlling DC motors, servo motors, and even stepper motors.

H-Bridge topology explained

Picture four switches arranged in an "H" shape – that's your basic H-bridge. These switches are typically transistors or MOSFETs. The motor sits right in the middle of the H. By flipping these switches on and off in different combinations, you can control the direction of current flow through the motor, making it spin forward or backward.

Here's how it works: When you close the top-left and bottom-right switches, current flows one way through the motor. Flip it to the top-right and bottom-left switches, and the current reverses, changing the motor's direction. It's like having a remote control for your motor's spin!

But be careful! Never close both switches on one side at the same time. That's a surefire way to create a short circuit and possibly fry your components. Most H-bridge designs include safeguards to prevent this "shoot-through" condition.

Advantages of H-Bridge circuits

H-bridges are super versatile and come with some cool perks:

- Bidirectional control: You can make your motor spin both ways without rewiring anything.

- Speed control: By using pulse-width modulation (PWM), you can adjust the motor's speed.

- Efficient braking: H-bridges let you stop motors quickly by shorting their terminals.

- Voltage flexibility: You can use a low-voltage control signal to manage a higher-voltage motor.

These advantages make H-bridges ideal for robotics, electric vehicles, and all sorts of automation projects where precise motor control is key.

Building a basic H-Bridge

While you can build an H-bridge from scratch using discrete components, it's often easier to use integrated circuits (ICs) designed for this purpose. Popular options include the L293D, L298N, and TA7257P.

If you're feeling adventurous, here's a simplified way to build your own:

- Choose four N-channel MOSFETs for the switches.

- Add protection diodes across each MOSFET to handle back-EMF from the motor.

- Use a microcontroller to generate the control signals.

- Include gate drivers to properly switch the high-side MOSFETs.

- Add decoupling capacitors to smooth out power supply fluctuations.

Remember, when working with motors, especially larger ones, you'll need to consider heat dissipation and current handling capabilities of your components.

By understanding H-bridge circuits, you're well on your way to mastering motor control. Whether you're building a simple robot or designing a complex industrial system, the H-bridge will be your trusty sidekick in getting those motors moving just the way you want them to.

Implementing Motor Control with Arduino

You're about to dive into the exciting world of motor control with Arduino! This versatile microcontroller platform makes it a breeze to get your motors spinning. Let's break down the process into manageable steps.

Setting up the hardware

To get started, you'll need a few key components:

- Arduino board (UNO or Mega 2560 work great)

- Motor driver (L298N or similar)

- DC motor

- Power supply (battery pack or adapter)

- Jumper wires

Begin by connecting your motor driver to the Arduino. The exact pins may vary depending on your setup, but here's a general guide:

- Connect the driver's enable pin (often labeled EN or PWM) to a PWM-capable pin on your Arduino (e.g., pin 3 or 6).

- Connect the driver's input pins (usually IN1 and IN2) to digital pins on your Arduino (e.g., pins 7 and 8).

- Connect the Arduino's ground to the driver's ground.

Next, hook up your DC motor to the output terminals on the motor driver. Finally, connect your power supply to the driver's power input, making sure to match the voltage requirements of your motor.

Writing the control code

Now that your hardware is set up, it's time to bring it to life with some code. Here's a simple sketch to get you started:

int enablePin = 3;

int in1Pin = 7;

int in2Pin = 8;

void setup() {

pinMode(enablePin, OUTPUT);

pinMode(in1Pin, OUTPUT);

pinMode(in2Pin, OUTPUT);

}

void loop() {

// Spin the motor forward

digitalWrite(in1Pin, HIGH);

digitalWrite(in2Pin, LOW);

analogWrite(enablePin, 200); // Speed control (0-255)

delay(2000);

// Stop the motor

digitalWrite(in1Pin, LOW);

digitalWrite(in2Pin, LOW);

delay(1000);

// Spin the motor backward

digitalWrite(in1Pin, LOW);

digitalWrite(in2Pin, HIGH);

analogWrite(enablePin, 200);

delay(2000);

}

This code will make your motor spin forward for 2 seconds, stop for 1 second, then spin backward for 2 seconds, repeating this cycle.

Troubleshooting common issues

If you're not seeing your motor move, don't worry! Here are some common hiccups and how to fix them:

- Check your connections: Make sure all wires are securely connected and in the correct pins.

- Verify power supply: Ensure your power source is providing enough voltage and current for your motor.

- Test the motor directly: Connect the motor directly to the power supply to confirm it's working.

- Double-check your code: Look for any typos or logic errors in your sketch.

- Monitor serial output: Add some Serial.println() statements to your code to help debug.

Remember, working with motors can be a bit tricky at first, but with some patience and troubleshooting, you'll soon have your projects moving smoothly!

Conclusion

Motor drivers play a crucial role in bringing motion to life in various projects, from simple DIY gadgets to complex industrial automation systems. Their ability to control speed, direction, and torque has a significant impact on the smooth operation of different types of motors. By understanding the basics of motor drivers, including the H-bridge circuit and various driver types, enthusiasts and professionals alike can harness the power of precise motor control to create innovative and efficient systems.

As we've seen, implementing motor control with Arduino opens up a world of possibilities for budding makers and seasoned engineers. The combination of hardware setup and software programming allows for fine-tuned control over motor behavior. While challenges may arise during the process, troubleshooting skills and a bit of patience can lead to successful motor-driven projects. With this knowledge in hand, you're now equipped to explore the exciting realm of motor control and bring your ideas to life.

FAQs

Q: What are the fundamental concepts of motor drives?

A: Motor drives refer to systems that incorporate a motor. These systems can have adjustable speeds, meaning the motor operates at multiple speeds, or variable speeds, where the motor's speed can be continuously adjusted.

Q: How should I select a motor driver for my motor?

A: When choosing a motor driver, start by determining the supply voltage, the output current, and the motor's power requirements. Motor drivers can be powered by batteries or connected directly to an electrical line, which influences the type of driver architecture needed.

Q: Can you explain the basic principle behind motor drivers?

A: A motor driver functions as a current amplifier. It takes a low-current control signal from a microcontroller and amplifies it to a higher current level that is capable of controlling and driving a motor. Typically, transistors are used to act as switches in this process, allowing the motor to operate in a specific direction.

Q: How do motor drivers operate?

A: Motor drivers, also known as control motors, are electronic devices or modules that manage the operation of electric motors. They act as an interface between a microcontroller (or another control system) and the motor, facilitating precise control over the motor's speed, direction, and other operational parameters.