What is a Motor Driver? Simple Guide to Powerful Motor Control

Published by Vineet Gupta on 17th Jul 2025

Motors are the most commonly used actuators in electronic devices. What makes them work so well? A motor driver acts as a vital interface between a microcontroller and the motor that lets you control speed, direction, and torque with precision.

Motor drivers have become indispensable in devices of all types. Your smartphone's vibration feature and CNC machines' precise movements both rely on these components. Motor drivers take input signals and boost current to control DC motors, stepper motors, and servo motors. They handle complex tasks that exceed a microcontroller's capabilities. Market projections show the motor driver IC sector will reach USD 1567.3 million by 2032, which proves their value in electronics. These drivers excel at power amplification and signal interpretation, unlike motor controllers that serve different purposes. The L298N motor driver shows this capability well - it manages two DC motors' speed and direction, which makes it ideal for Arduino projects. This piece will help you understand how motor drivers work, their varieties, and their role in control systems.

Table of Contents:

- Understanding the Role of a Motor Driver in Control Systems

- Types of Motor Drives and Their Use Cases

- Materials and Methods: Building and Testing Motor Driver Circuits

- How Motor Drivers Work: Signal Amplification and Direction Control

- Limitations and Design Constraints of Motor Drivers

- Conclusion

- FAQs

Understanding the Role of a Motor Driver in Control Systems

Motor drivers are the foundations of any electronic control system that runs motors. You'll quickly find that microcontrollers can't directly power most motors when you design circuits to control them. Let me explain why motor drivers are needed, what they do, and how they're different from motor controllers.

Why microcontrollers alone can't drive motors

Microcontrollers face big limitations with direct motor control. Their I/O pins output only a small current—typically 10-20mA. This falls way short for most motors that need 400mA to 1A or more to work. Even the smallest DC motors need more current than what a microcontroller can safely give.

Voltage limits create another problem. Microcontrollers run at 3.3V to 5V logic levels, while motors need 12V, 24V, or higher to reach full speed. Try to run a motor directly and you'll get poor results—the motor might barely turn or stay still under load.

Motors also create something dangerous called back EMF (electromotive force) as their magnetic fields collapse during operation. This voltage spike can fry the sensitive output transistors in your microcontroller if you connect them directly. That's why direct motor-to-microcontroller connections don't work and can destroy your components.

What does a motor driver do in a circuit?

Motor drivers bridge the gap between control signals and motor operation. We used them as power amplifiers that take low-current control signals from the microcontroller and turn them into higher-power signals for motor coils. This lets your 5V microcontroller signal control motors that run at much higher voltages and currents.

Most drivers use an H-bridge setup—a group of power transistors (usually MOSFETs or BJTs) that allow two-way control. The H-bridge lets current flow through the motor in both directions for forward and reverse operation. The microcontroller sends PWM (Pulse Width Modulation) signals, and the H-bridge transistors switch to control both direction and speed through variable power delivery.

Today's motor drivers come with built-in protection features that keep both motors and control electronics safe. These features include overcurrent protection, short-circuit protection, and thermal shutdown systems. They prevent damage from stalls, wrong wiring, or too much load that could wreck your system.

Motor driver vs motor controller: Key differences

People often mix them up, but motor drivers and controllers do different jobs in electronic systems. Here's what sets them apart:

-

Input signal requirements: Motor drivers need simple control signals like PWM and direction logic from an external microcontroller. Motor controllers have their own microcontroller that makes these signals.

-

Functionality: Drivers handle power and signal amplification by using motor driving chips. Controllers add smarts and processing power for complex control algorithms.

-

Interface methods: Drivers need basic digital signals (PWM, logic pins). Controllers give you more options like serial, USB, RC, or analog voltage inputs.

-

Standalone capability: Drivers can't work alone—they need external control signals. Controllers give you a complete package that works with just power and command inputs.

Motor drivers manage electrical power to motors, while controllers handle both logic and power. Simple projects work best with a motor driver and your existing microcontroller. This combo is a great way to get flexibility at a good price.

Types of Motor Drives and Their Use Cases

Motor drives exist in many configurations. Each one serves specific applications based on how it controls and performs. Knowing the different types of motor drivers helps you pick the right one that meets your project needs. These drivers range from simple speed control to exact positioning, and each type gives unique benefits depending on what you want to control.

Brushed DC motor drivers for simple speed control

Brushed DC motor drivers remain popular because they are economical and simple to use. These drivers control motors with physical brushes that make mechanical contact with the commutator. This enables straightforward current flow control. The simple design makes brushed DC motors easier to drive with simpler circuitry than other motor types.

The MP6615, a typical brushed DC motor driver, delivers up to 8A of continuous output current. It includes protection features like over-voltage protection (OVP), over-current protection (OCP), and thermal shutdown. These drivers use H-bridge configurations with four N-channel power MOSFETs that enable bidirectional control with 100% duty cycle operation.

You'll find brushed DC motor drivers in automotive systems like power windows, windshield wipers, and seat position modules. They work great in robotics to control movement and in toys where you need simple and affordable solutions. These drivers let you adjust speed and torque through voltage or PWM signals, making them perfect when you need straightforward motion control.

Brushed DC motor drivers with Hall sensors

BLDC motor drivers represent a step up from traditional brushed systems. They work with motors that use permanent magnets on the rotor and electromagnets on the stator. This brushless design leads to better efficiency, reliability, and longer life.

Hall sensors play a vital role in these drivers. They detect the rotor's position and send immediate feedback to the controller. This tells the system which stator coils need power for continuous motion. The MP6545 three-phase power stage IC works with input voltages from 4.5V to 45V and delivers up to 2.5A of output current per phase.

These drivers with Hall sensors shine when you need low-speed control. They work better than sensorless systems that struggle to measure back-EMF for rotor position. The drivers prove invaluable when applications demand high torque at zero speed or very high motor speeds, where back-EMF alone can't reliably detect position.

Stepper motor drivers for precise positioning

Stepper motor drivers control motors that move in exact steps. This makes them perfect for applications needing precise positioning. The drivers turn pulse signals into mechanical rotation with specific step angles—usually 0.36°, 0.72°, 0.9°, or 1.8°—allowing for highly accurate movement control.

These drivers work on a simple principle: one pulse equals one step. This relationship creates two main benefits. The motor's rotation matches the number of pulses sent to the driver. The motor's speed relates directly to how fast these pulses come in.

You'll see stepper motor drivers in CNC machines, 3D printers, scientific equipment, and positioning systems. They excel when you need high precision and repeatability. The drivers can maintain holding torque even when stopped, which helps in vertical applications where you need to hold position without extra brakes.

Servo motor drivers with closed-loop control

Servo motor drivers stand out as the most advanced motor control systems. They use closed-loop control that constantly watches and adjusts performance. These drivers use feedback devices—typically encoders—that track the motor's actual position, speed, or torque and compare it to what you want.

The control loop in a servo system processes hundreds of times faster than you can blink. Multiple control loops work together. The current loop takes commands and powers the motor. The velocity loop uses sensor feedback to fix speed errors. The position loop checks target positions against actual ones and tells the velocity loop what to do.

These drivers give exceptional performance when you need fast movement and exact positioning. They work best in robotics, CNC machinery, and automated manufacturing where you need quick acceleration, deceleration, and precise position control. Though more complex than other types, servo systems deliver unmatched results in demanding applications that need both speed and precision.

Materials and Methods: Building and Testing Motor Driver Circuits

Building motor driver circuits needs the right components and a solid grasp of their electrical characteristics. The simple contours stay the same whether you build a basic DC motor controller or a complex stepper driver. Let's look at everything in components and testing methods for motor driver circuits.

Common components: MOSFETs, BJTs, and PWM controllers

Motor driver circuits depend on the core team of semiconductor components that manage power switching requirements. Engineers prefer MOSFETs (Metal-Oxide-Semiconductor Field-Effect Transistors) over BJTs (Bipolar Junction Transistors) in modern motor drivers. MOSFETs offer lower on-resistance and better efficiency. BJTs need substantial base current because they are current-controlled devices. MOSFETs are voltage-controlled and need minimal input current to switch large loads. This makes them ideal especially when you have PWM applications that need faster switching.

N-channel MOSFETs like the 2N7000 work with up to 60V DC at 200mA continuously and can handle burst capabilities of 500mA. Your circuit design should include a 10kΩ resistor between the MOSFET's gate and source pins. This keeps the gate switched off when no current flows.

PWM (Pulse Width Modulation) controls motor speed. This method adjusts the average voltage to the motor by switching power on and off at different duty cycles. The motor speed depends on the ratio of "on" time to the total period, which determines the average voltage.

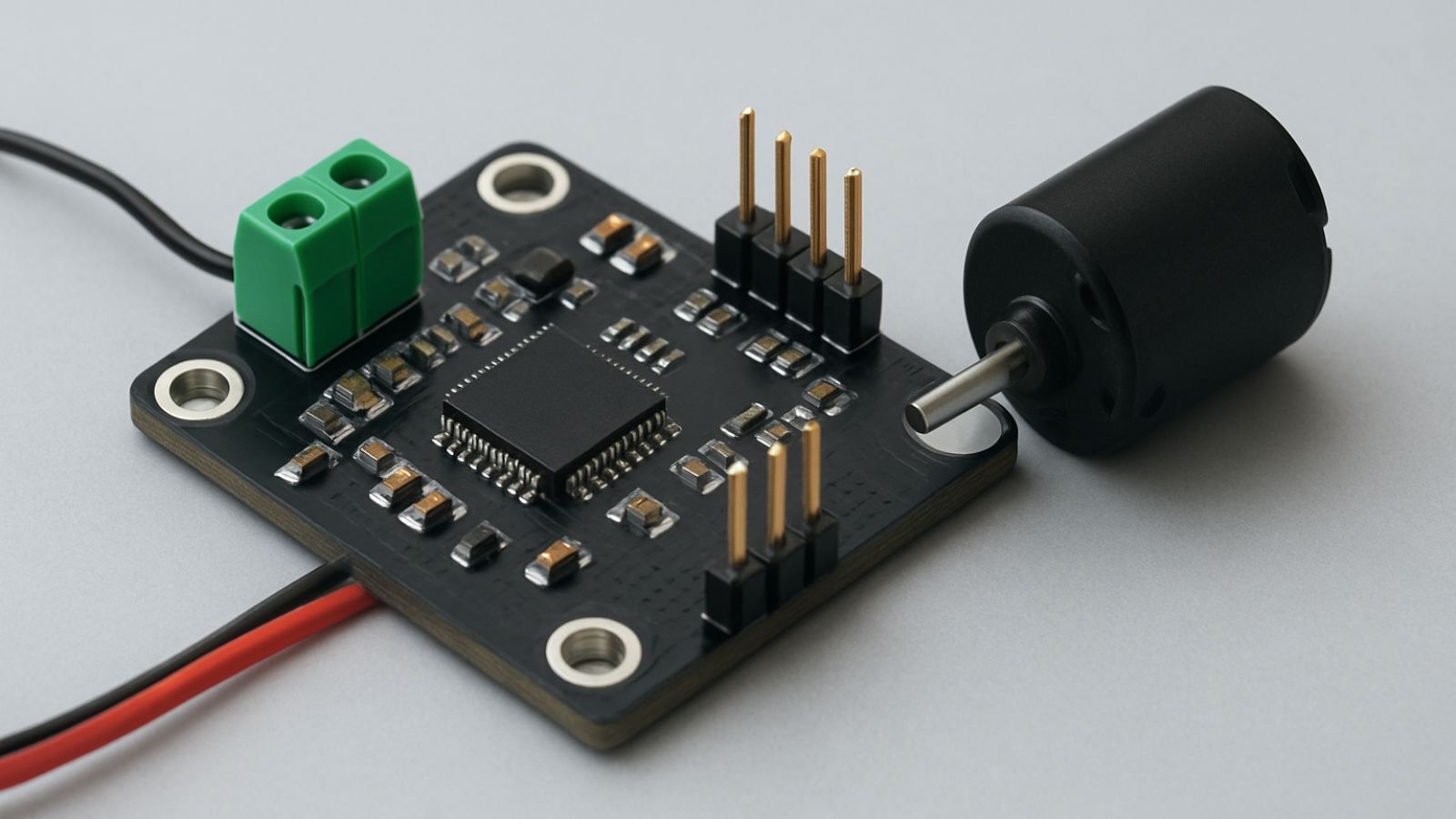

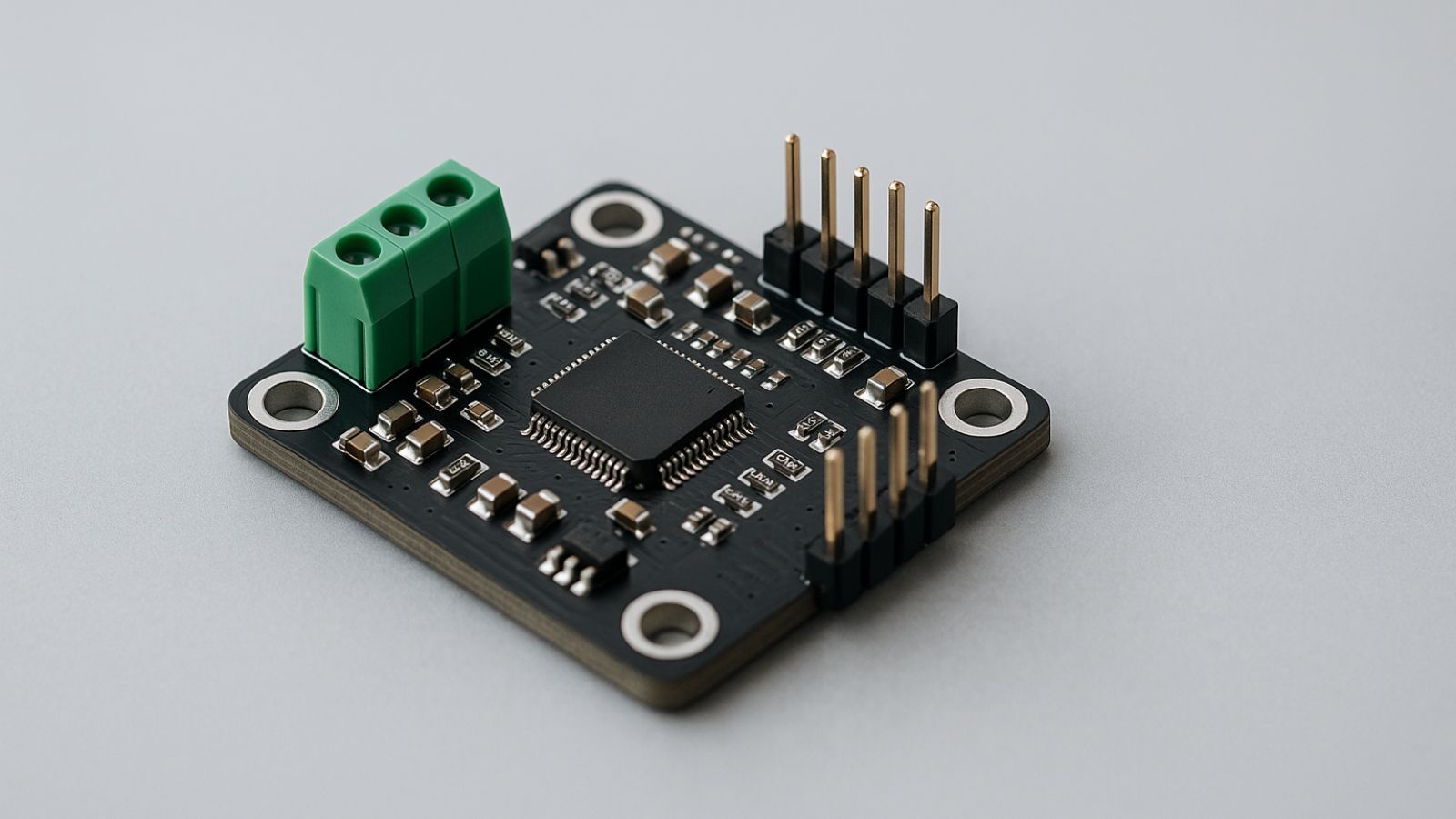

Test setup using Arduino and L298N module

The Arduino microcontroller paired with an L298N dual H-bridge motor driver creates a popular test setup. This module controls two DC motors at once and handles voltages from 5V to 35V with peak currents up to 2A. The L298N comes with a built-in 5V regulator that works with a jumper at the time motor supply voltage stays at 12V or below.

A simple test setup connects the L298N's enable pins (ENA, ENB) to Arduino PWM-capable pins (pins 9 and 3). The input pins (IN1, IN2, IN3, IN4) connect to standard digital output pins (pins 8, 7, 5, 4). PWM signals through enable pins control motor speed. Input pins set rotation direction by managing the H-bridge configuration.

A typical circuit includes:

-

Arduino UNO as the controller

-

L298N motor driver module

-

Two 12V DC motors

-

External power supply (9-12V)

-

Jumper wires for connections

Voltage and current requirements for different motors

The right driver selection needs a clear understanding of motor electrical specs. The L298N module has about 2V voltage drop across its internal transistors. A 12V power supply delivers only 10V to the motor, which means slower maximum speed. A 14V power supply works better with a 12V motor to make up for this voltage drop.

Motors of all sizes need different amounts of current. Small DC motors pull 400-500mA while larger industrial motors might need several amperes. Your driver should handle more current than your motor's maximum draw. Remember that stall current can be 3-10 times more than running current.

Three-phase systems calculate horsepower using this formula: Horsepower = Voltage × Amperage × % Efficiency × Power Factor × 1.73/746. The National Electrical Code tables provide standard full-load current values for specific motor types if you don't want to measure directly.

How Motor Drivers Work: Signal Amplification and Direction Control

Motor driver circuits work by turning weak control signals into powerful outputs that can move motors. These critical components use several mechanisms to ensure motors run properly whatever the load conditions. A clear understanding of motor drivers helps explain their role in electronic systems.

PWM signal interpretation and voltage stepping

Pulse Width Modulation (PWM) serves as the life-blood of modern motor control and lets users adjust speed precisely without energy waste. The motor driver reads these quick on/off pulses and sends the right voltage to the motor. The duty cycle—the ratio between "on" time and total cycle period—sets the average voltage the motor gets. To name just one example, the motor receives full bus voltage when the transistor stays open 100% of the time, and half the bus voltage at 50% duty cycle.

Brushless DC motor drivers use high PWM frequencies—usually above 50 kHz—which allows proper current control with enough cycles during each commutation step. The high frequency helps the motor run smoothly since current doesn't reach steady state between cycles. Lower PWM frequencies of just a few thousand Hertz tend to make the rotor vibrate and create noise you can hear. That's why designers pick frequencies above what humans can hear (20 kHz).

H-Bridge circuit for bidirectional control

The H-bridge circuit is the life-blood of two-way motor control. Its name comes from looking like the letter "H" when drawn with the motor on the center bar. Four switching elements—usually MOSFETs or BJTs—control how current flows through the motor. The motor changes direction when diagonal pairs of these switches activate and reverse voltage polarity at the motor terminals.

H-bridges do more than just control direction. The motor rotates forward or backward when diagonal pairs (S1+S4 or S2+S3) turn on. The motor stops quickly through dynamic braking when both high-side switches activate and connect its terminals. This setup works great for applications that need precise stopping points because it turns the motor's movement energy into electrical current.

Overcurrent and thermal protection mechanisms

Modern motor drivers come with smart protection features that keep both the driver and motor safe from damage. The overcurrent protection watches current flow and shuts down the driver if it spots too much current. This feature becomes crucial when motors stall and current jumps to 3-10 times normal levels.

Temperature sensors in thermal protection shut things down when they get too hot. The ALM2402-Q1 driver uses system feedback and shutdown options that prevent damage from high temperatures, which helps the system last longer. Motor thermal winding protection stops excessive heat that could break down winding insulation permanently. These protection features work together to keep everything running smoothly even in tough conditions.

Limitations and Design Constraints of Motor Drivers

Motor drivers, despite their advanced features, have practical limits you need to think about when designing. These components handle power amplification between microcontrollers and motors. Learning their constraints helps you avoid performance issues and circuit failures.

Current handling limits of ICs like L293D and TB6612FNG

Current carrying capacity is a big limit for motor driver ICs. The L293D, a popular quadruple half-H driver, delivers only 600mA of continuous current and up to 1.2A peak current per channel. This might not be enough when you need higher torque, since many motors pull more current under load. The TB6612FNG works better with 1.2A continuous current and 3.2A peak current per channel. Motors draw maximum current when held still, so stall conditions need extra attention.

Going over these current ratings affects how well your system works and how reliable it is. A motor trying to pull more current than its driver can handle leads to poor performance that's hard to fix. Your choice of driver with the right current capabilities becomes vital, especially with large motors or when you need high torque.

Voltage drop and heat dissipation issues

Voltage drops in motor driver circuits create tough performance challenges. The L293D loses about 2V across its internal transistors. This means a 12V power supply might only give 10V to the motor, which limits its speed and torque. This becomes a bigger issue when you need precise voltage control.

Heat buildup is another vital concern. Electric current flowing through motor control circuits creates heat that can damage parts and reduce efficiency. Your PCB design plays a key role in managing heat. Continuous copper thermal pads create good heat pathways. You should also connect thermal vias between top and bottom layers without thermal relief connections. This lets heat spread across both surfaces.

Compatibility with high-torque motors

High-torque motors bring their own set of challenges to driver selection. Stepper motors, which we used for precise positioning, have specific limits in speed versus torque. Picking the right driver becomes even more important with high-torque applications since poor choices lead to noise and failures.

Some driver-motor pairs just don't work well together. The EVO Motion controller can't run gear-reduced high-torque motors fast enough while keeping noise levels acceptable due to its hardware limits. You need to watch stall current ratings closely. Many drivers fall short of the maximum rated stall current that high-torque motors need, especially when starting to move. To get the best performance with high-torque motors, always check both continuous and peak current specs against what your motor needs.

Conclusion

Motor drivers are the vital link between control electronics and motor operation in countless applications. This piece has shown how these essential components increase weak microcontroller signals into powerful outputs that can drive motors of all types. On top of that, it explains why microcontrollers can't power motors by themselves due to current and voltage limitations, among other risks like damage from back EMF.

Your motor driver selection needs to account for several key factors. The driver's current handling capacity must match your motor's needs, particularly the stall current that can be substantially higher than running current. You should also account for voltage drops across driver components affecting motor performance. Heat dissipation requirements based on operating conditions need careful review.

Today's motor drivers showcase impressive capabilities in a variety of applications. The L298N modules control DC motors in hobby projects while sophisticated servo drivers handle closed-loop control in industrial systems. These components make precise movement control possible. A well-chosen motor driver turns simple electronic signals into mechanical action - from a smartphone's vibration to a CNC machine's exact positioning.

Motor drivers will evolve with better efficiency, enhanced protection, and broader compatibility as technology advances. These components are the foundations of countless electronic devices we use daily, though many overlook them in system designs. A solid grasp of their operation and limits will give you the knowledge you need to implement them successfully in your next motor control project.

FAQs

Q. What is the primary function of a motor driver?

A. A motor driver acts as an interface between a microcontroller and a motor, amplifying low-current control signals to provide the high-current and voltage required by the motor. It enables precise control of motor speed, direction, and torque while offering protection features.

Q. Why can't microcontrollers directly power motors?

A. Microcontrollers have limited current output (typically 10-20mA) and operate at low voltages (3.3V to 5V), which is insufficient for most motors. Additionally, motors can generate dangerous back EMF that could damage microcontrollers if connected directly.

Q. How does a motor driver control motor speed and direction?

A. Motor drivers use PWM (Pulse Width Modulation) signals to control speed by rapidly switching power on and off at varying duty cycles. For direction control, they employ H-bridge circuits that can reverse voltage polarity across motor terminals by activating different pairs of switches.

Q. What's the difference between a motor driver and a motor controller?

A. A motor driver focuses on power amplification and signal interpretation, requiring external control signals. A motor controller includes onboard intelligence for generating control signals and often offers higher-level interfaces, making it a more complete solution for motor control.

Q. What are some common limitations of motor drivers?

A. Motor drivers have current handling limits that can affect performance with high-torque motors. They also experience voltage drops across internal components, which can reduce available motor voltage. Heat dissipation is another concern, especially in high-current applications, requiring careful thermal management in circuit design.